NewTechWood Siding Installation Guide

NewTechWood siding installation is more than just slapping up some panels; it’s about transforming your home’s exterior with a durable, sustainable, and stylish material. This guide walks you through every step, from initial preparation to the final finishing touches, ensuring a professional-looking result. We’ll cover everything from choosing the right profile to mastering tricky corners and dealing with potential problems along the way. Get ready to upgrade your curb appeal!

This comprehensive guide will equip you with the knowledge and confidence to tackle your NewTechWood siding project successfully. We’ll break down the process into manageable steps, providing clear instructions and helpful tips to avoid common pitfalls. Whether you’re a seasoned DIYer or a first-timer, this guide will be your invaluable resource.

Introduction to NewTechWood Siding

NewTechWood siding offers a compelling alternative to traditional wood and vinyl siding, boasting a blend of aesthetics, durability, and sustainability. It’s engineered from a composite of recycled wood fibers and high-density polyethylene (HDPE), resulting in a product that mimics the look of natural wood but surpasses it in performance and longevity. This material resists rot, warping, insect infestation, and fading, making it a low-maintenance and cost-effective choice for homeowners.

NewTechWood siding provides significant advantages over traditional materials. Unlike natural wood, it requires minimal upkeep, eliminating the need for regular painting, staining, or sealing. Compared to vinyl, it offers a more realistic wood-grain texture and a higher-end aesthetic appeal, often indistinguishable from real wood at a distance. Furthermore, its superior strength and impact resistance make it a more durable and long-lasting option.

NewTechWood Siding Profiles and Applications

NewTechWood offers a variety of siding profiles designed to complement different architectural styles and homeowner preferences. Each profile features distinct characteristics impacting its visual appeal and suitability for specific applications. Understanding these differences is key to selecting the ideal siding for your project.

- Grooved Siding: This classic profile closely resembles traditional clapboard siding, offering a timeless and versatile look suitable for various home styles, from colonial to craftsman.

- Shiplap Siding: Characterized by its clean lines and overlapping planks, shiplap siding provides a modern and sleek appearance, often preferred for contemporary or farmhouse-style homes.

- Board and Batten Siding: This profile features wide vertical planks with narrow battens covering the seams, creating a bold and rustic look ideal for rural or farmhouse settings.

- Shake Siding: Mimicking the look of natural wood shakes, this profile adds a textured and rustic charm to homes, complementing mountain or cabin-style architecture.

Environmental Impact and Sustainability of NewTechWood Siding

NewTechWood siding’s composition significantly contributes to its environmental friendliness. The utilization of recycled wood fiber reduces reliance on newly harvested timber, lessening the impact on forests. The incorporation of HDPE, a recyclable plastic, further minimizes waste and promotes resource conservation. The product’s long lifespan also reduces the need for frequent replacements, lowering the overall environmental footprint associated with siding materials. Moreover, NewTechWood is manufactured using sustainable practices, minimizing energy consumption and emissions during production. The reduced need for maintenance and the lack of harmful chemical treatments further enhance its eco-friendly profile. For instance, a comparison study might show that over a 50-year lifespan, NewTechWood siding produces significantly less greenhouse gas emissions than traditional wood siding due to reduced need for re-painting and replacement.

Preparation for Installation

Getting ready for your NewTechWood siding installation is crucial for a smooth and long-lasting result. Proper preparation minimizes potential issues and ensures a professional-looking finish. This section details the necessary tools, site preparation steps, and a pre-installation checklist to help you get started.

Before you begin, gather all the necessary tools and materials. Having everything on hand will streamline the process and prevent frustrating delays.

Tools and Equipment

A successful NewTechWood siding installation requires the right tools. The list below covers the essentials, but specific needs may vary depending on the project’s complexity and scale.

- Measuring Tape: Accurate measurements are paramount for precise cutting and efficient material usage.

- Level: Maintaining consistent levels throughout the installation is key to achieving a professional finish and preventing water damage.

- Circular Saw with Fine-Tooth Blade: A fine-tooth blade minimizes chipping and ensures clean cuts on the siding panels.

- Jigsaw: Useful for cutting around corners and difficult-to-reach areas.

- Safety Glasses and Gloves: Protecting your eyes and hands is essential throughout the installation process.

- Drill with appropriate drill bits: Used for fastening the siding panels to the wall framing.

- Caulk Gun: For sealing gaps and joints to prevent water infiltration.

- Hammer: Useful for driving nails or other fasteners.

- Utility Knife: For trimming and cutting smaller pieces of siding or underlayment.

- Pencil: For marking cutting lines and other measurements.

Site Preparation

Proper site preparation is essential for a successful siding installation. This involves accurate measurements, thorough cleaning, and ensuring a stable and suitable surface for attachment.

Begin by taking precise measurements of the area to be sided. Accurate measurements will determine the amount of siding needed and minimize waste. Next, thoroughly clean the surface. Remove any loose debris, dirt, or old paint. A clean surface ensures proper adhesion of the siding and underlayment.

Finally, assess the condition of the underlying structure. Ensure that the wall framing is sound and capable of supporting the weight of the siding. Repair any damaged areas before beginning the installation.

Pre-Installation Inspection Checklist

A pre-installation inspection is a critical step to identify and address any potential issues before proceeding. This checklist will help you ensure everything is in place for a smooth installation.

| Item | Inspection | Action |

|---|---|---|

| Building Permits | Are all necessary permits obtained? | Obtain any missing permits before starting. |

| Surface Preparation | Is the surface clean, dry, and free of debris? | Clean and repair the surface as needed. |

| Wall Framing | Is the wall framing sound and properly braced? | Repair or reinforce any damaged areas. |

| Materials | Are all necessary materials on hand and accounted for? | Order any missing materials. |

| Tools | Are all necessary tools in good working order? | Repair or replace any faulty tools. |

| Weather Conditions | Are the weather conditions suitable for installation? (Avoid extreme temperatures and rain.) | Postpone installation if weather conditions are unfavorable. |

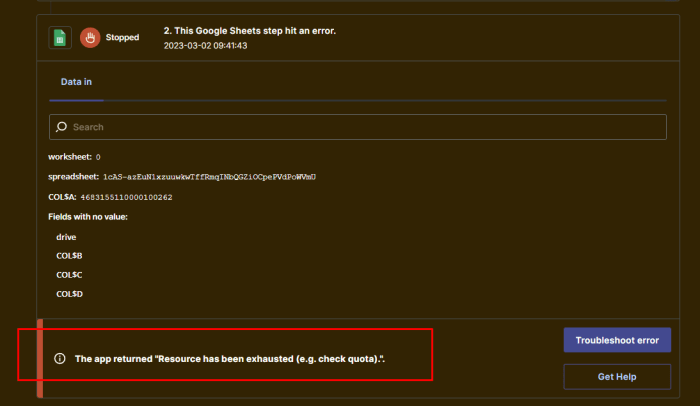

Installation Process: Newtechwood Siding Installation

Source: insided.com

Installing NewTechWood siding is a straightforward process, but careful attention to detail ensures a beautiful and long-lasting finish. This section provides a step-by-step guide, covering material preparation, installation techniques, and troubleshooting common issues. Remember to always consult the manufacturer’s instructions specific to your NewTechWood product for the most accurate and up-to-date information.

Step-by-Step Installation Guide

Proper installation is key to maximizing the lifespan and aesthetic appeal of your NewTechWood siding. The following table Articulates the process, materials, and potential problems you might encounter.

| Step | Material | Procedure | Troubleshooting |

|---|---|---|---|

| 1. Measuring and Cutting | Measuring tape, saw (circular saw with fine-tooth blade recommended), pencil. | Accurately measure and mark the siding pieces to the required length. Use a sharp saw to make clean, straight cuts, avoiding splintering. For intricate cuts, a jigsaw may be necessary. Pre-drill pilot holes for fasteners to prevent splitting. | If the cut is uneven, use a hand plane or sandpaper to smooth the edges. Avoid forcing the saw; a slow, steady cut is best. If splitting occurs, use wood filler to repair it. |

| 2. Installing Starter Strips | Starter strips, screws, drill/driver | Install starter strips along the bottom edge of the wall, ensuring they are level and plumb. Secure them using appropriate screws, spaced according to manufacturer’s recommendations. | If the starter strip is uneven, adjust it before securing it. Use shims if necessary to level the strip. Ensure screws are properly tightened to avoid loosening. |

| 3. Attaching Siding Panels | Siding panels, screws, drill/driver, level | Slide the first panel into the starter strip, ensuring proper overlap. Secure the panel using screws, spacing them evenly and according to manufacturer’s specifications. Use a level to ensure each panel is installed straight and plumb. Continue installing panels, overlapping them as per the manufacturer’s instructions. | If a panel is misaligned, carefully remove it and reposition it. Check the level frequently to prevent cumulative errors. Over-tightening screws can cause cracking; use consistent pressure. |

| 4. Corner and J-Channel Installation | Corner trim, J-channel, screws, drill/driver | Use corner trim to neatly finish exterior corners. Install J-channel around windows and doors for a clean, professional look. Secure these components with screws, ensuring proper alignment and spacing. | Use caulk to seal any gaps between trim and siding. Ensure the trim is properly aligned to avoid gaps. Pre-drilling pilot holes will prevent cracking. |

| 5. Finishing and Caulking | Caulk, caulking gun | Apply caulk to all seams and joints to seal against moisture and air infiltration. Smooth the caulk for a neat finish. | Choose a high-quality exterior-grade caulk appropriate for the climate. Allow the caulk to fully cure before painting. |

Cutting and Fastening Techniques

Cutting NewTechWood siding requires precision to maintain its aesthetic appeal. A fine-tooth blade on a circular saw is ideal for straight cuts. For intricate cuts, a jigsaw is preferable. Always pre-drill pilot holes before fastening to prevent splitting. Fasteners should be driven straight and snug, but avoid over-tightening. The recommended screw type and spacing will be specified in the manufacturer’s instructions.

Handling Corners, Windows, and Doors

Properly finishing corners, windows, and doors is crucial for a professional-looking installation. Use specialized corner trim pieces to neatly cover exterior corners. J-channel is used around windows and doors to provide a clean transition between the siding and the window or door frame. Always ensure proper alignment and sealing to prevent water infiltration. Use caulk to seal all gaps between the siding and trim pieces.

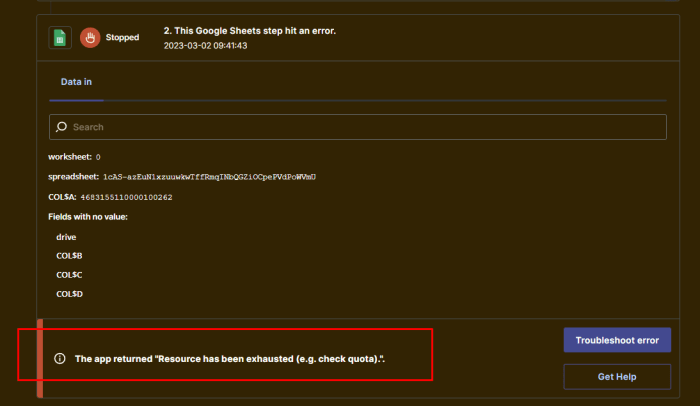

Finishing Touches and Maintenance

Source: sstatic.net

You’ve successfully installed your NewTechWood siding! Now it’s time to add those finishing touches and learn how to keep your siding looking its best for years to come. Proper installation of trim and accessories, along with a regular cleaning schedule, will ensure your investment remains beautiful and functional.

Adding trim and accessories not only enhances the aesthetic appeal but also protects the edges of your siding from the elements. Careful attention to detail during this phase will significantly improve the overall look and longevity of your project. We’ll cover the best practices for installing these elements, ensuring a seamless and professional finish. Proper maintenance is equally crucial; we’ll Artikel simple cleaning methods to keep your NewTechWood siding looking pristine.

Installing Trim and Accessories

Installing trim and accessories is the final step in achieving a professional-looking finish. Start by carefully measuring and cutting the trim pieces to fit snugly around windows, doors, and corners. Use appropriate fasteners, such as stainless steel screws, to secure the trim, ensuring they are countersunk to avoid damaging the siding. Remember to maintain consistent spacing and alignment for a clean, uniform look. For corner pieces, ensure a tight fit to prevent water infiltration. J-channel and other accessories should be installed according to the manufacturer’s instructions to ensure proper water management. Paying attention to these details will make a noticeable difference in the final product.

Cleaning and Maintaining NewTechWood Siding

Regular cleaning is essential to maintain the beauty and longevity of your NewTechWood siding. A simple solution of mild detergent and water, applied with a soft brush or sponge, is usually sufficient to remove dirt and debris. Rinse thoroughly with clean water to remove any soap residue. Avoid using harsh chemicals or abrasive cleaners, as these can damage the surface of the siding. For stubborn stains, a pressure washer can be used, but maintain a safe distance to avoid damaging the siding. It’s important to clean your siding at least once or twice a year, depending on your climate and environmental conditions. Consider more frequent cleaning in areas with high pollen or pollution.

Common Installation Problems and Solutions, Newtechwood siding installation

Understanding potential problems and their solutions can save you time and frustration during installation. Here’s a list of common issues and how to address them:

- Problem: Gaps between siding panels. Solution: Ensure proper overlap and use appropriate fasteners to secure the panels tightly. Check for any warping or damage to the panels themselves.

- Problem: Difficulty cutting siding. Solution: Use a sharp blade, such as a fine-toothed saw or a circular saw with a fine-tooth blade. Make sure the blade is clean and free of debris for clean cuts.

- Problem: Water damage. Solution: Ensure proper flashing and sealing around windows and doors. Check for gaps in the siding and seal them with appropriate caulk. Proper installation of J-channel and other accessories is also crucial.

- Problem: Uneven siding alignment. Solution: Use a level to ensure proper alignment during installation. Adjust as needed to create a straight and uniform look.

- Problem: Stripped screw holes.Solution: Use pilot holes to prevent stripping when installing screws. Choose screws appropriate for the material.

Advanced Installation Techniques

Source: massivepeak.com

So, you’ve mastered the basics of NewTechWood siding installation. Now let’s delve into some more advanced techniques to handle trickier situations and ensure a truly professional finish. This section covers adapting your installation method to different weather conditions and tackling complex projects like curved walls.

This section will cover various installation methods optimized for different weather conditions, troubleshooting common challenges encountered during complex installations, and a detailed visual guide on proper flashing and sealing to prevent water damage.

Installation Methods for Varying Weather Conditions

Different weather conditions significantly impact siding installation. Extreme heat can cause expansion and warping, while cold temperatures can make materials brittle and difficult to work with. Wind can also affect the installation process, potentially dislodging improperly secured panels. Therefore, adjusting the installation method to the specific conditions is crucial for optimal results. For instance, in extremely hot weather, pre-drilling pilot holes can help prevent cracking, and allowing for extra expansion space between panels is essential. Conversely, in cold weather, using a heat gun to warm the materials slightly can improve flexibility and reduce the risk of breakage. High winds might necessitate additional fasteners or temporary bracing until the adhesive cures completely.

Addressing Challenges in Complex Installations

Complex installations, particularly those involving curved walls, require careful planning and specialized techniques. Curved walls present a challenge because standard rectangular siding panels don’t conform easily to the curve. One common solution involves using smaller, more flexible pieces of siding, meticulously cut to fit the curve’s radius. Another method involves pre-bending or shaping the panels using heat and careful manipulation, though this requires practice and expertise. Precise measurements and diligent fitting are crucial to avoid gaps or overlaps that compromise the aesthetic appeal and weather resistance of the installation. Remember to always check the manufacturer’s guidelines for specific recommendations on bending or shaping their products.

Proper Flashing and Sealing Techniques

Proper flashing and sealing are critical to prevent water damage. Water intrusion is a major concern in any siding installation, and neglecting proper sealing can lead to costly repairs down the line. Imagine a visual guide showing a close-up of a corner joint. First, a flexible flashing strip is installed, extending beyond the edges of the overlapping panels. This flashing is carefully tucked under the top panel and folded neatly over the lower panel, creating a waterproof barrier. Then, a high-quality, weather-resistant sealant is applied to all seams and joints, ensuring complete coverage. Another section of the visual guide depicts the installation of J channels around windows and doors. These channels provide a neat, finished look while simultaneously guiding water away from these vulnerable areas. The J-channel is installed first, then the siding is carefully fitted into the channel, creating a watertight seal. Finally, the visual guide would showcase the sealing around penetrations like pipes and vents. A sealant is applied liberally around the penetration point, ensuring that no gaps are left for water to enter. The entire area should be carefully inspected to ensure that no gaps or cracks are present. This detailed approach guarantees a long-lasting, watertight installation.

Cost Analysis and Budgeting

Planning the budget for your NewTechWood siding installation is crucial to avoid unexpected expenses. A well-structured budget ensures a smooth project execution and helps you make informed decisions throughout the process. This section Illustrates a sample budget and factors influencing the overall cost.

Understanding the various cost components involved in a NewTechWood siding installation project is key to effective budgeting. Factors such as material selection, project size, and labor costs significantly impact the final price.

Sample Budget Breakdown

This example budget is for a medium-sized project (approximately 1500 square feet of siding). Remember, your actual costs will vary depending on your specific needs and location.

| Cost Category | Estimated Cost | Notes |

|---|---|---|

| Materials (NewTechWood Siding, fasteners, underlayment) | $8,000 – $12,000 | Cost varies based on siding type, color, and quantity needed. |

| Labor (Installation, preparation, cleanup) | $5,000 – $8,000 | Labor rates vary by region and contractor experience. |

| Permits and Inspections | $500 – $1,000 | Permit costs vary by location and project scope. |

| Waste Removal | $200 – $500 | Cost depends on the amount of waste generated. |

| Contingency (Unexpected expenses) | $500 – $1,000 | Always include a buffer for unforeseen issues. |

| Total Estimated Cost | $14,200 – $22,500 | This is a range; the actual cost will vary. |

Factors Influencing Overall Cost

Several key factors influence the total cost of a NewTechWood siding project. Careful consideration of these factors during the planning phase is essential for accurate budgeting.

- Siding Type: Different NewTechWood siding options (e.g., different profiles, colors, finishes) have varying price points. Premium options will naturally be more expensive.

- Project Size: The total area requiring siding directly impacts material and labor costs. Larger projects require more materials and more labor hours.

- Labor Rates: Labor costs vary significantly based on geographic location, contractor experience, and demand. Obtaining multiple quotes is highly recommended.

- Complexity of the Installation: Projects with intricate designs or requiring significant preparation work (e.g., removing existing siding) will generally cost more.

- Permitting Fees: Permitting fees vary widely depending on local regulations and the project’s complexity.

Cost-Saving Strategies

While saving money is important, it’s crucial to avoid compromising on the quality of materials and workmanship. Here are some strategies to help manage costs without sacrificing quality:

- Shop Around for Materials: Compare prices from multiple suppliers to find the best deals on NewTechWood siding and other necessary materials.

- Consider DIY (Do-It-Yourself) for Certain Tasks: If you have experience with home improvement, you might consider tackling some simpler tasks like preparing the surface yourself, potentially saving on labor costs. However, always assess your skills realistically to avoid mistakes that could cost more in the long run.

- Plan Your Project Carefully: Detailed planning minimizes waste and reduces the need for additional materials or labor. Accurate measurements and a well-defined scope are essential.

- Negotiate with Contractors: Obtain multiple quotes from different contractors and negotiate for the best possible price while ensuring they have the necessary experience and insurance.

- Stagger the Project: Breaking down the project into smaller phases can help manage cash flow and potentially reduce overall costs by allowing for more flexibility in scheduling.

Safety Precautions

Installing NewTechWood siding, while relatively straightforward, involves working at heights and with tools that can cause injury if not handled correctly. Prioritizing safety is crucial for a successful and injury-free project. This section Artikels essential safety measures to ensure your well-being throughout the installation process.

Safety isn’t just about avoiding accidents; it’s about working efficiently and confidently. By following these precautions, you’ll minimize risks and ensure a smooth installation.

Personal Protective Equipment (PPE)

Appropriate personal protective equipment is non-negotiable for any siding installation. Failure to use PPE can lead to serious injuries, ranging from minor cuts and scrapes to severe eye damage or head trauma. Using the right PPE demonstrates a commitment to safety and reduces the likelihood of accidents.

- Safety Glasses or Goggles: Protect your eyes from flying debris, dust, and chemical splashes from cleaning agents.

- Work Gloves: Prevent cuts and abrasions from sharp edges of siding materials and tools.

- Hearing Protection: Reduce noise exposure from power tools, particularly if working for extended periods.

- Dust Mask or Respirator: Protect your lungs from inhaling sawdust and other airborne particles.

- Hard Hat: Essential when working at heights to protect against falling objects.

- Safety Harness and Fall Protection System: Mandatory when working on ladders or scaffolding above a certain height (consult local regulations).

- Steel-toed Boots: Protect your feet from dropped tools or materials.

Potential Hazards and Risk Mitigation

Several hazards are inherent in siding installation. Understanding these hazards and implementing appropriate mitigation strategies is key to preventing accidents.

- Falls from Heights: Always use a stable ladder or scaffolding, ensuring it’s properly secured. Use a safety harness and fall protection system when working at heights exceeding recommended limits. Regularly inspect ladders and scaffolding for damage before each use.

- Cuts and Abrasions: Handle siding materials and tools carefully. Wear appropriate gloves and use caution when using sharp tools like utility knives or saws. Dispose of sharp debris safely.

- Exposure to Chemicals: When using cleaning agents, follow the manufacturer’s instructions carefully and ensure adequate ventilation. Wear appropriate gloves and eye protection.

- Electrical Hazards: Be aware of overhead power lines and underground electrical cables. Maintain a safe distance and call your local utility company if you suspect proximity to electrical lines. Never work with electrical tools in wet conditions.

- Tool Misuse: Always use tools according to the manufacturer’s instructions. Regularly inspect tools for damage and ensure they are properly maintained. Never force a tool; use the correct tool for the job.

Closure

Source: githubusercontent.com

Installing NewTechWood siding is a rewarding project that can significantly enhance your home’s value and aesthetics. By following this guide’s step-by-step instructions and safety precautions, you can achieve a professional-looking finish that will stand the test of time. Remember to plan carefully, gather the necessary tools, and take your time—the result will be well worth the effort. Now go forth and clad your home in stylish, sustainable beauty!

FAQ Compilation

Can I install NewTechWood siding myself?

While DIY is possible, complex installations might require professional help. Assess your skills honestly before starting.

How long does NewTechWood siding last?

With proper maintenance, NewTechWood siding can last for decades, significantly longer than many traditional materials.

What kind of warranty does NewTechWood offer?

Check the manufacturer’s website for specific warranty details, as they vary by product and region.

How much does NewTechWood siding cost compared to other options?

NewTechWood’s cost is generally higher than vinyl but often less expensive than real wood, offering a balance of price and quality.

What are the best cleaning products for NewTechWood siding?

Consult the manufacturer’s recommendations; generally, mild soap and water are sufficient for regular cleaning.

Comments are closed.