Fire Extinguisher Inspection OSHA A Practical Guide

Fire extinguisher inspection OSHA compliance is crucial for workplace safety. This guide breaks down OSHA regulations, inspection procedures, and record-keeping best practices, ensuring your fire extinguishers are ready when needed. We’ll cover everything from identifying different extinguisher types and their specific inspection needs to understanding proper maintenance and corrective actions. Get ready to become a fire safety pro!

We’ll walk you through a step-by-step inspection process, including visual checks for damage, pressure tests, and proper documentation. You’ll learn how to identify potential hazards and address them effectively, minimizing risks and ensuring your workplace is compliant with OSHA standards. This isn’t just about ticking boxes; it’s about safeguarding lives and property.

OSHA Regulations on Fire Extinguisher Inspections

Source: co.ke

OSHA’s regulations regarding fire extinguisher inspections are crucial for workplace safety. These regulations aim to ensure that fire extinguishers are readily available and in proper working order to effectively combat fires, minimizing potential harm to employees and property. Failure to comply can result in significant fines and legal repercussions.

The primary OSHA standard governing fire extinguisher inspection and maintenance is 29 CFR 1910.157. This standard doesn’t prescribe a single, universally applicable inspection frequency; instead, it emphasizes the importance of regular inspections based on the type of extinguisher and the specific workplace hazards. The frequency and thoroughness of inspections are directly tied to the potential risk of fire within a given environment.

Inspection Frequency and Extinguisher Types

The frequency of fire extinguisher inspections is not a fixed number but depends heavily on the type of extinguisher and the work environment. While OSHA doesn’t explicitly state specific frequencies for each extinguisher type, a generally accepted practice is to perform monthly visual inspections and more thorough annual inspections. High-risk environments, such as those with flammable materials or frequent welding operations, may require more frequent inspections. For example, a monthly inspection might involve a quick visual check for obstructions, damage, or pressure gauge readings, while an annual inspection would include a more detailed examination, potentially involving a qualified technician.

Employer Responsibilities Regarding Fire Extinguisher Maintenance and Record-Keeping

Employers are responsible for ensuring that all fire extinguishers are properly maintained and inspected. This includes designating a responsible person to conduct the inspections, providing training on proper inspection techniques, and maintaining accurate records of all inspections. These records should document the date of the inspection, the extinguisher’s identification number, the inspector’s name, and any issues found. Failing to maintain these records can lead to OSHA citations, as they serve as proof of compliance. Furthermore, employers must ensure that extinguishers are properly serviced and recharged by qualified personnel as needed.

Examples of OSHA Citations Related to Inadequate Fire Extinguisher Inspection Programs

OSHA frequently cites employers for deficiencies in their fire extinguisher inspection programs. Common violations include:

- Lack of a documented inspection program.

- Insufficient inspection frequency, failing to account for workplace hazards.

- Improperly trained personnel conducting inspections.

- Failure to maintain accurate records of inspections and maintenance.

- Extinguishers were found to be inoperable or lacking proper pressure.

For instance, a company operating a welding shop might receive a citation for not performing monthly inspections on their extinguishers, especially given the increased fire risk associated with welding. Another example might be a factory that fails to keep adequate records of extinguisher maintenance, making it impossible to demonstrate compliance with OSHA regulations.

“Employers are responsible for providing a safe and healthful workplace, and this includes ensuring that fire extinguishers are properly maintained and inspected.” – OSHA

Fire Extinguisher Inspection Procedures

Regular fire extinguisher inspections are crucial for workplace safety and compliance with OSHA regulations. A well-maintained extinguisher is your first line of defense against a fire, so thorough and consistent inspections are non-negotiable. This section details the proper procedures to ensure your fire extinguishers are ready when needed.

Step-by-Step Inspection Guide, Fire extinguisher inspection osha

Following a systematic approach ensures no critical element is overlooked during the inspection. This step-by-step guide provides a framework for a comprehensive assessment.

- Visual Inspection: Begin with a thorough visual check of the extinguisher’s exterior. Look for any signs of damage, such as dents, rust, or corrosion. Check for obstructions around the extinguisher that might impede access in an emergency.

- Gauge Check (if applicable): Many extinguishers have a pressure gauge. Note the gauge reading; it should be within the acceptable range indicated on the gauge itself. A gauge reading outside this range may indicate low pressure or overpressure, requiring immediate attention.

- Hose and Nozzle Check: Inspect the hose for any cracks, kinks, or damage. Ensure the nozzle is free from obstructions and in good working order. If the extinguisher has a pin or tamper seal, verify its presence and intact condition.

- Weight Check (for certain extinguisher types): Some extinguishers require a weight check to assess the pressure level. This involves weighing the extinguisher and comparing the weight to the manufacturer’s specifications. A significant weight difference may signal a problem.

- Documentation: After completing the inspection, record your findings on the provided checklist. This documentation serves as proof of compliance and helps track the maintenance history of the extinguisher.

Inspection Checklist

A well-structured checklist streamlines the inspection process and ensures consistency. This table provides a framework for recording your observations.

| Item | Check | Notes | Date |

|---|---|---|---|

| Exterior Condition (dents, rust, corrosion) | |||

| Gauge Pressure (if applicable) | Record pressure reading | ||

| Hose and Nozzle Condition (cracks, kinks, obstructions) | |||

| Pin/Tamper Seal (present and intact) | |||

| Weight (if applicable) | Record weight and compare to manufacturer specifications |

Visual Inspection Details

A comprehensive visual inspection is the cornerstone of effective fire extinguisher maintenance. This involves a detailed examination of the extinguisher’s physical condition. Look for signs of damage, including dents, punctures, rust, corrosion, or any signs of physical impact. Check for any obstructions that could block access to the extinguisher, such as boxes, equipment, or other obstacles. Pay close attention to the nozzle and hose for any cracks, kinks, or damage that could compromise their functionality. Inspect the cylinder for any signs of leakage or discoloration.

Weighing a Fire Extinguisher

Weighing a fire extinguisher provides an indirect assessment of its internal pressure. This method is primarily used for certain types of extinguishers, not all. The procedure involves using a calibrated scale to determine the extinguisher’s weight. This weight is then compared to the manufacturer’s specified weight for a fully charged extinguisher. A significant discrepancy could indicate a loss of pressure due to leakage or other issues. For example, if a CO2 extinguisher’s weight is significantly lower than the manufacturer’s specification, it could suggest a loss of CO2, necessitating immediate attention and potentially recharging. Remember to always consult the manufacturer’s instructions for specific weight requirements and safety procedures.

Types of Fire Extinguishers and Their Inspection Needs

Understanding the different types of fire extinguishers and their specific inspection requirements is crucial for maintaining workplace safety and ensuring your fire suppression equipment is ready when needed. Regular inspections, beyond simply checking the pressure gauge, are vital to prevent malfunctions and ensure effectiveness during a fire emergency. Failing to properly inspect and maintain fire extinguishers can have serious consequences.

Different classes of fire extinguishers are designed to tackle specific types of fires, and their inspection procedures vary accordingly. Improper use or maintenance of the wrong type of extinguisher on a particular class of fire can exacerbate the situation, leading to increased property damage and potentially endangering lives. Therefore, knowing the extinguisher’s class and its associated inspection requirements is non-negotiable.

Fire Extinguisher Class A Inspection

Regular inspections of Class A fire extinguishers, designed for ordinary combustibles like wood and paper, focus on ensuring the extinguisher’s ability to effectively discharge water or water-based agents.

- Check the pressure gauge for proper pressure range.

- Inspect the hose for any kinks, damage, or leaks.

- Examine the nozzle for obstructions or damage.

- Verify the extinguisher’s weight to ensure it’s fully charged.

- Check the exterior for any dents, rust, or damage that might compromise its integrity.

Fire Extinguisher Class B Inspection

Class B extinguishers combat flammable liquids like gasoline and oil. Their inspection requires a focus on the agent’s discharge capabilities and the prevention of leaks.

- Inspect the pressure gauge for proper pressure.

- Check the nozzle for any obstructions or damage.

- Examine the hose for kinks, cracks, or damage.

- Look for any signs of leakage around the valve or cylinder.

- Ensure the extinguisher’s handle and trigger mechanism operate smoothly.

Fire Extinguisher Class C Inspection

Class C extinguishers are used on electrically energized fires. Safety is paramount during their inspection, as any electrical contact during the process could be hazardous.

- Always ensure the power is OFF before inspecting a Class C extinguisher.

- Inspect the pressure gauge for proper pressure.

- Check the nozzle for obstructions or damage.

- Examine the hose for kinks, cracks, or damage.

- Verify the extinguisher’s weight to ensure it’s fully charged.

Fire Extinguisher Class D Inspection

Class D extinguishers tackle combustible metals. These require specialized handling and inspection due to the unique nature of the fires they combat.

- Inspect the pressure gauge for proper pressure (if applicable; some Class D extinguishers are not pressure-operated).

- Check for any signs of leakage or damage to the container.

- Ensure the extinguishing agent is not contaminated or solidified.

- Verify the integrity of the seals and any safety mechanisms.

- Follow the manufacturer’s specific inspection guidelines, as these vary greatly depending on the extinguishing agent.

Fire Extinguisher Class K Inspection

Class K extinguishers are designed for cooking oils and fats. Their inspection requires attention to the potential for residue buildup and the need for specialized cleaning procedures.

- Inspect the pressure gauge for proper pressure.

- Check the nozzle for obstructions or damage.

- Examine the hose for kinks, cracks, or damage.

- Look for any signs of residue buildup inside the extinguisher or nozzle.

- Follow manufacturer recommendations for cleaning and maintenance.

Pressure Gauge Inspection Procedures

Inspecting the pressure gauge is a crucial part of any fire extinguisher inspection. The procedure is generally similar across extinguisher types, but variations exist depending on the gauge design. Always refer to the manufacturer’s instructions for specific guidance.

- Visual Inspection: Check the gauge for any damage, cracks, or obstructions. Ensure the needle is clearly visible and moves freely.

- Pressure Reading: Note the pressure reading and compare it to the manufacturer’s recommended operating range, usually indicated on the gauge itself or in the extinguisher’s manual. A reading outside the acceptable range indicates the need for servicing or recharging.

- Gauge Type Considerations: Different gauges may have slightly different interpretations of the pressure readings. Some use a colored zone to indicate the operational range. Others use numerical markings.

Inspecting Specific Extinguisher Types

CO2 extinguishers require careful inspection of the horn and discharge mechanism for any obstructions or damage. Dry chemical extinguishers need a check for caking or clumping of the agent. Water extinguishers should be inspected for signs of corrosion or leakage. Always prioritize safety and follow the manufacturer’s instructions for each specific type.

Documentation and Record Keeping

Keeping accurate and up-to-date records of your fire extinguisher inspections is crucial for maintaining workplace safety and demonstrating compliance with OSHA regulations. Proper documentation protects your business from potential liabilities and shows a commitment to employee well-being. Neglecting this aspect can lead to penalties and, more importantly, put lives at risk.

Proper documentation allows you to easily track the condition of your fire extinguishers, identify any issues promptly, and ensure timely maintenance and repairs. This proactive approach minimizes the risk of equipment failure during an emergency.

Fire Extinguisher Inspection Record Template

A well-designed inspection record template streamlines the process and ensures all necessary information is captured consistently. Here’s a sample template you can adapt to your needs:

| Date | Extinguisher ID | Location | Inspection Results (Pass/Fail) | Corrective Actions (if any) | Inspector Name |

|---|---|---|---|---|---|

| 2024-10-27 | ABC-123 | Main Office – Reception | Pass | N/A | John Doe |

| 2024-10-27 | DEF-456 | Warehouse – Aisle 3 | Fail – Pressure Gauge Low | Recharged and pressure tested. | John Doe |

Importance of Accurate and Up-to-Date Documentation

Accurate records are essential for demonstrating compliance during OSHA inspections. They provide verifiable proof that you’ve followed established procedures and addressed any identified problems. Incomplete or inaccurate records can lead to fines and other penalties. Furthermore, up-to-date records facilitate proactive maintenance, preventing equipment malfunctions and ensuring preparedness for emergencies. Imagine a scenario where a fire occurs, and your records show a critical extinguisher was overdue for inspection—the consequences could be severe.

Best Practices for Storing and Managing Fire Extinguisher Inspection Records

Maintain a centralized system for storing your inspection records. This could be a physical file, a dedicated spreadsheet, or a database. Regardless of the method, ensure records are easily accessible and organized. Consider using a system that allows for easy searching and retrieval of specific records. Regularly back up your records to prevent data loss. For digital records, password protection is crucial. Establish a clear retention policy specifying how long records must be kept (OSHA guidelines should be consulted).

Examples of Acceptable and Unacceptable Record-Keeping Methods

Acceptable methods include using dedicated spreadsheet software (like Microsoft Excel or Google Sheets), a database management system, or purpose-built fire safety management software. These methods allow for easy organization, searching, and reporting. A well-maintained physical file system with clearly labeled folders can also be acceptable, provided it’s consistently updated and easily accessible.

Unacceptable methods include haphazardly recording information on scraps of paper, relying solely on memory, or using inconsistent formats that make data retrieval difficult. These methods fail to provide the necessary audit trail and increase the risk of errors and omissions. Using a shared digital document without version control and access limitations is also unacceptable, as it can lead to inconsistencies and data corruption.

Training and Employee Responsibilities

Source: insurecompliance.net

Effective fire extinguisher training is crucial for workplace safety. Employees need to understand their roles in maintaining a safe environment, including the proper inspection and use of fire extinguishers. This training ensures everyone is prepared to react appropriately in case of a fire, minimizing potential damage and injury.

Regular training ensures compliance with OSHA regulations and reduces the risk of workplace fires. A well-trained workforce is better equipped to handle fire emergencies and can significantly impact the outcome of a fire incident.

Fire Extinguisher Inspection Training Module

This module covers the visual inspection of fire extinguishers, including checking for damage, and pressure indicators, and ensuring the extinguisher is properly mounted and accessible. Employees will learn to identify potential issues and report them to designated personnel. The training will also cover the different types of fire extinguishers and their appropriate uses. Hands-on practice with extinguisher inspection procedures will be provided, followed by a written test to ensure comprehension.

The training will include a demonstration of the PASS method (Pull, Aim, Squeeze, Sweep) for using a fire extinguisher effectively and safely. Emphasis will be placed on the importance of knowing the limitations of fire extinguishers and when to evacuate a building. Participants will also be educated on the proper procedures for reporting any malfunctions or deficiencies.

Roles and Responsibilities of Designated Personnel

Designated personnel, often trained safety officers or facility managers, are responsible for the overall maintenance and inspection program for fire extinguishers. Their responsibilities include scheduling regular inspections, coordinating repairs and replacements, maintaining accurate records, and ensuring that all employees receive appropriate training. They are the point of contact for reporting any issues related to fire extinguishers.

These individuals will also be responsible for ensuring that fire extinguishers are correctly located, easily accessible, and marked. They must also stay updated on relevant OSHA regulations and best practices for fire safety. They are ultimately accountable for the effectiveness of the fire extinguisher maintenance program.

Employee Awareness of Fire Extinguisher Locations and Usage

Employees must be aware of the locations of all fire extinguishers within their work area. Regular training and signage will reinforce this knowledge. Knowing the location of the nearest extinguisher can significantly reduce response time in the event of a fire. Understanding the different types of extinguishers and their appropriate uses is equally important. Improper use can be dangerous and ineffective.

Regular fire drills and emergency response training can reinforce employee awareness and preparedness. These drills provide valuable practical experience in using fire extinguishers and evacuating the building safely. Employees should be encouraged to ask questions and clarify any uncertainties they may have regarding fire safety procedures.

Consequences of Neglecting Fire Extinguisher Maintenance and Inspection

Neglecting fire extinguisher maintenance and inspection can lead to serious consequences, including equipment failure during a fire emergency. A malfunctioning extinguisher can put lives and property at risk, leading to potentially devastating losses. OSHA fines and legal liabilities are also potential outcomes of non-compliance.

Furthermore, a lack of proper maintenance and inspection can create a hazardous work environment, potentially leading to workplace accidents and injuries. Failure to comply with OSHA regulations could result in significant penalties and damage to the company’s reputation. A proactive approach to fire safety, including regular inspection and maintenance, is essential for protecting employees and assets.

Corrective Actions and Maintenance: Fire Extinguisher Inspection Osha

Regular fire extinguisher inspections aren’t just about ticking boxes; they’re crucial for ensuring your workplace’s safety. Finding problems during an inspection means taking swift and appropriate action to get your extinguishers back in top working order. This section details the procedures for addressing those issues, from minor fixes to complete servicing.

Addressing identified issues during inspection requires a systematic approach. Failure to properly maintain fire extinguishers can lead to equipment malfunction during an emergency, potentially resulting in serious injury or property damage. Therefore, prompt corrective action is paramount.

Corrective Action Procedures

When a problem is identified during inspection, the first step is to document the issue. This documentation should include the extinguisher’s identification number, the specific problem, the date the problem was discovered, and the inspector’s name or initials. Next, the extinguisher should be tagged as “out of service” to prevent accidental use. This tag should indicate the nature of the problem. Finally, the appropriate corrective action should be taken, ranging from minor adjustments to professional servicing.

Examples of Necessary Corrective Actions

Different problems require different solutions. For instance, a gauge showing low pressure might simply need recharging, while a damaged hose or nozzle requires replacement. A corroded cylinder might necessitate the complete replacement of the extinguisher. A missing or damaged safety pin needs immediate attention. A clogged nozzle could require specialized cleaning and potentially a partial discharge to clear the obstruction. Each issue needs a specific response to restore the extinguisher to full functionality and safety.

Tagging and Removing Out-of-Service Extinguishers

Once an extinguisher is deemed out of service, it must be marked with a “Do Not Use” tag. This tag should be easily visible and prominently displayed. The extinguisher should then be removed from its designated location and stored in a secure area away from active units. This prevents accidental use of a malfunctioning extinguisher and ensures that functioning units are readily available. A log should be maintained, tracking the location of the out-of-service extinguisher and detailing the repair or replacement process.

Recharging and Servicing Fire Extinguishers

Recharging and servicing fire extinguishers should only be performed by trained and qualified personnel. This is not a DIY project. Improper recharging can compromise the extinguisher’s effectiveness and potentially create a hazardous situation. The process typically involves weighing the extinguisher to determine the amount of extinguishing agent needed, and then carefully refilling the cylinder. Pressure testing is also critical to ensure the cylinder can withstand the pressure of the agent. Following the manufacturer’s instructions is paramount for safe and effective recharging. Servicing might involve replacing components like hoses, nozzles, or pressure gauges, as well as a thorough inspection of the cylinder for any signs of damage or corrosion. Always ensure you use the correct type and amount of extinguishing agent specified for each extinguisher type.

Visual Aids for Fire Extinguisher Inspection

Understanding the visual aspects of fire extinguisher maintenance is crucial for ensuring workplace safety. Regular visual inspections are the first line of defense against malfunctioning equipment. This section provides visual descriptions to aid in your inspections.

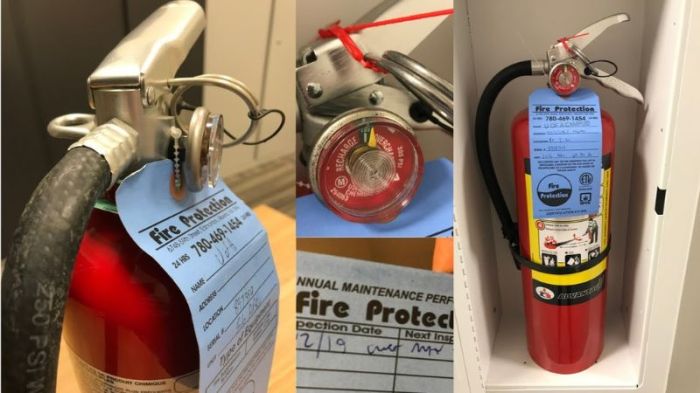

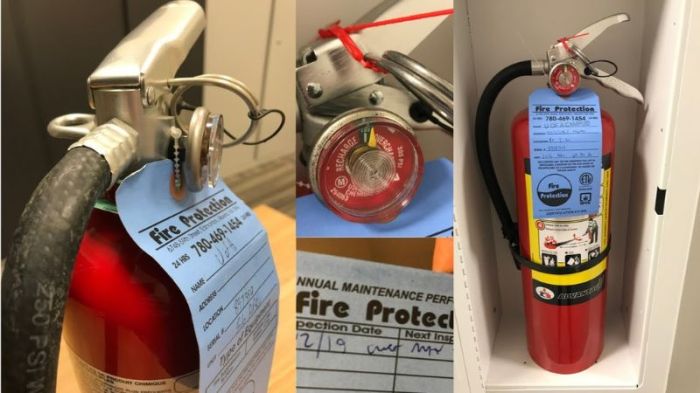

Appearance of a Properly Maintained Fire Extinguisher

A properly maintained fire extinguisher presents a clean and unblemished appearance. The cylinder should be free from rust, dents, or significant scratches. The pressure gauge, if present, should indicate that the extinguisher is properly charged, typically within the green operational range. All labels, including the type of fire extinguisher, operating instructions, and manufacturer information, should be visible, legible, and undamaged. The nozzle or hose should be securely attached and free from damage or kinks. The extinguisher’s pin or tamper seal should be intact, indicating it hasn’t been tampered with. The extinguisher should be stored in a readily accessible, clearly marked location, away from heat sources and potential hazards.

Appearance of a Damaged, Corroded, or Tampered Fire Extinguisher

A damaged extinguisher might exhibit obvious signs like deep dents, significant rust, or cracks in the cylinder. Corrosion can manifest as pitting, flaking paint, or significant surface discoloration. Tampering is indicated by a missing or broken tamper seal, a damaged or missing pin, or evidence of forced entry or unauthorized use. The pressure gauge might be broken or indicate dangerously low pressure (outside the green range). The nozzle or hose could be damaged, detached, or obstructed. The labels may be torn, faded, or completely missing, making identification and use difficult. For instance, a fire extinguisher dropped from a significant height might show dents and possible internal damage, even if the external damage seems minor.

Visual Indicators Requiring Immediate Attention

Several visual cues demand immediate attention. A pressure gauge reading outside the designated operational range (typically green) strongly suggests a problem requiring immediate professional service. A noticeably leaking extinguisher, evidenced by visible residue or dampness around the nozzle or cylinder, requires immediate isolation and professional attention. A missing or damaged tamper seal indicates potential tampering and necessitates a thorough inspection by a qualified technician. Visible corrosion or significant damage to the cylinder poses a serious safety hazard and necessitates replacement. A severely dented extinguisher might have compromised structural integrity and should be replaced.

Appearance of an Improperly Stored or Maintained Fire Extinguisher

An improperly stored or maintained extinguisher might be covered in dust, grime, or other debris, indicating neglect. It might be stored in an inaccessible location, obstructed by other materials, or exposed to harsh environmental conditions such as extreme heat or moisture. The extinguisher might be stored near incompatible materials or in a way that hinders quick access during an emergency. Paint might be chipped or peeling due to exposure to the elements. The extinguisher might be lying on its side, which can damage internal components. For example, an extinguisher stored in a damp basement might show signs of significant rust and corrosion, even if it’s relatively new.

Final Conclusion

Source: seechange.com

Regular fire extinguisher inspections, guided by OSHA regulations, are vital for workplace safety. By understanding the specific requirements for different extinguisher types, conducting thorough inspections, and maintaining meticulous records, you can significantly reduce the risk of fire-related incidents. Remember, proactive maintenance and employee training are key to creating a safe and compliant environment. Don’t just meet the minimum standards – exceed them!

FAQ

What happens if I fail a fire extinguisher inspection?

OSHA can issue citations and penalties. You’ll need to correct the deficiencies immediately and potentially face fines.

How often should I train employees on fire extinguisher use?

OSHA doesn’t specify a frequency, but regular training (at least annually) is recommended, especially after any changes in equipment or procedures.

Can I use a generic inspection checklist, or do I need one specific to my extinguisher types?

While a generic checklist can be a starting point, you should tailor it to the specific types and classes of extinguishers in your workplace for maximum effectiveness.

What if an extinguisher is damaged beyond repair?

Tag it as “out of service,” remove it from its location, and replace it with a properly functioning extinguisher. Keep detailed records of the removal and replacement.

Where can I find more detailed OSHA regulations on fire extinguishers?

Consult the OSHA website (osha.gov) and search for relevant standards and publications. You can also contact your local OSHA office for assistance.

Comments are closed.