Fire Cabinets OSHA Safety and Compliance

Fire Cabinets OSHA: Understanding and complying with OSHA regulations for fire cabinets is crucial for workplace safety. This guide breaks down everything you need to know, from selecting the right cabinet for your needs to mastering emergency procedures. We’ll explore the various types of fire cabinets, their proper placement, essential maintenance, and the importance of clear labeling. Get ready to become a fire safety expert!

We’ll cover OSHA standards, penalties for non-compliance, and best practices for storing flammable and combustible materials. This isn’t just about ticking boxes; it’s about protecting your workplace and your team. Let’s dive in and ensure your fire safety plan is up to OSHA standards.

OSHA Regulations on Fire Cabinets: Fire Cabinets Osha

OSHA doesn’t have a specific standard solely dedicated to “fire cabinets.” Instead, regulations regarding the storage of flammable and combustible materials indirectly address the use of fire cabinets as a means of compliant storage. The overarching goal is to prevent fires and mitigate their impact in the workplace. Compliance relies on understanding and adhering to several relevant standards.

Flammable and Combustible Liquid Storage

OSHA’s primary focus regarding flammable and combustible materials centers around their proper storage and handling. Standards like 29 CFR 1910.106 (Flammable and Combustible Liquids) dictate the requirements for storage, including the type of containers used, the amount allowed in a given area, and the separation distances from ignition sources. Fire cabinets, when properly selected and used, contribute significantly to meeting these requirements. The selection of the cabinet itself must be appropriate for the specific hazard class of the stored liquids. For instance, a cabinet rated for Class I liquids wouldn’t be suitable for storing Class III liquids.

Fire Cabinet Selection and Placement

The selection of a fire cabinet is critical and should consider factors such as the type and quantity of flammable materials stored, the cabinet’s fire resistance rating, and its construction materials. OSHA doesn’t specify particular cabinet brands or models but implicitly mandates choosing a cabinet that meets or exceeds the requirements of 29 CFR 1910.106 for the specific hazard class of stored materials. Placement is equally important. Cabinets should be located in areas with adequate ventilation, away from ignition sources (heaters, electrical equipment), and easily accessible for emergency response. Clear signage indicating the cabinet’s contents is also necessary.

Fire Cabinet Maintenance

Regular maintenance is vital to ensure the continued effectiveness of fire cabinets. This includes regular inspections for damage, ensuring proper closure and sealing, and checking for any signs of leaks or spills. OSHA doesn’t provide a specific maintenance schedule, but the implied expectation is that cabinets are kept in good working order and inspected frequently enough to prevent hazardous conditions. Any damage or malfunction should be promptly addressed to prevent potential fire hazards.

Penalties for Non-Compliance

Non-compliance with OSHA regulations related to the storage of flammable and combustible materials, which includes improper use of fire cabinets, can result in significant penalties. These penalties can include fines, ranging from several hundred to thousands of dollars per violation, depending on the severity of the infraction and the employer’s history of compliance. OSHA can also issue citations and require employers to correct violations. In serious cases, repeated violations or those resulting in injury or death can lead to even more substantial fines and potential criminal charges.

Fire Cabinet Types and Ratings

| Cabinet Type | Fire Resistance Rating | Suitable Materials | Notes |

|---|---|---|---|

| Type I | 30 minutes or more | Flammable liquids (Class IA, IB, IC) | Meets stringent fire resistance standards. |

| Type II | 15-30 minutes | Flammable liquids (Class II, II) | Offers intermediate fire protection. |

| Type III | Less than 15 minutes | Combustible liquids (Class IB) | Provides limited fire protection. |

| Safety Cabinets (General Purpose) | Varies widely; check manufacturer specifications | Various materials, often with limitations | Check individual ratings and suitability for intended materials. |

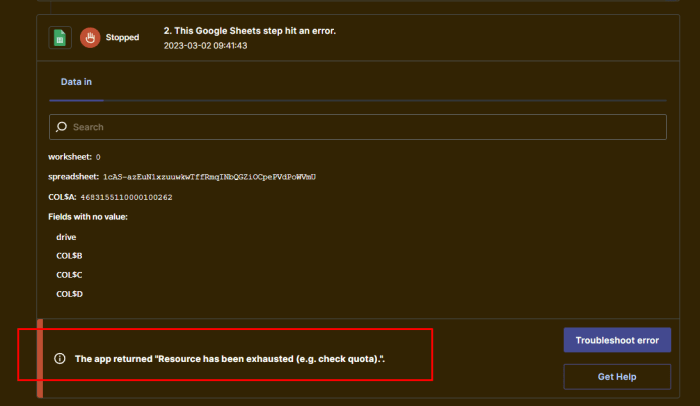

Types of Fire Cabinets and Their Uses

Source: insided.com

Fire cabinets are essential for workplace safety, providing readily accessible fire suppression agents. Choosing the right type depends heavily on the types of fire hazards present in a specific location. Understanding the different classes of fires and the cabinets designed to combat them is crucial for effective fire prevention and control.

Different fire cabinets are designed to extinguish different classes of fires, categorized by the type of fuel involved. The construction materials and safety features also vary depending on the intended application and the specific hazards being addressed. Proper selection and maintenance are key to ensuring the effectiveness of these vital safety devices.

Class A Fire Cabinet Contents and Applications

Class A fire cabinets contain agents designed to extinguish fires involving ordinary combustible materials like wood, paper, cloth, and trash. These agents typically work by cooling the burning material and smothering the flames. Common extinguishing agents include water-based solutions, sometimes with additives to improve performance. The cabinets themselves are usually constructed from durable steel to protect the contents and withstand potential impacts during use. They are commonly found in offices, schools, and residential settings where Class A fire risks are prevalent.

- Advantages: Relatively inexpensive, widely available, effective on common combustible materials.

- Disadvantages: Ineffective on flammable liquids or electrical fires; water can cause damage to certain materials.

Class B Fire Cabinet Contents and Applications

Class B fire cabinets are designed for fires involving flammable liquids such as gasoline, oil, grease, and solvents. These cabinets typically contain dry chemical agents or foam extinguishers that work by interrupting the chemical chain reaction of combustion or by smothering the flames. Construction materials are similar to Class A cabinets—robust steel—but may incorporate additional features for handling potentially corrosive extinguishing agents. They are essential in garages, workshops, and industrial settings where flammable liquids are stored or used.

- Advantages: Effective on flammable liquid fires; relatively easy to use.

- Disadvantages: May not be effective on Class A or C fires; dry chemical agents can leave a residue.

Class C Fire Cabinet Contents and Applications

Class C fire cabinets are specifically designed for electrical fires involving energized electrical equipment. They typically contain dry chemical agents, carbon dioxide (CO2), or other non-conductive extinguishing agents to prevent electrical shock and extinguish the fire. The cabinets themselves often feature additional safety features, such as grounding mechanisms, to minimize the risk of electric shock during use. They are commonly found in server rooms, electrical substations, and industrial facilities with extensive electrical equipment.

- Advantages: Safe for use on energized electrical equipment; effective on electrical fires.

- Disadvantages: May not be effective on Class A or B fires; CO2 can displace oxygen and create an asphyxiation hazard in enclosed spaces.

Class D Fire Cabinet Contents and Applications

Class D fire cabinets address fires involving combustible metals such as magnesium, titanium, and sodium. These fires require specialized extinguishing agents, often dry powders specifically formulated to cool and smother the burning metal. The cabinets are usually constructed from robust materials capable of withstanding the intense heat generated by these types of fires. They are found in industrial settings where combustible metals are processed or stored.

- Advantages: Effective on combustible metal fires; designed for high-temperature applications.

- Disadvantages: Specialized agents are required; expensive and less commonly found.

Class K Fire Cabinet Contents and Applications

Class K fire cabinets are designed for fires involving cooking oils and fats, common in commercial kitchens. These cabinets usually contain wet chemical agents that saponify (form soap) with the burning oil, creating a layer that suppresses the flames. The cabinets are often constructed with materials resistant to high temperatures and grease.

- Advantages: Effective on cooking oil and grease fires; specifically designed for commercial kitchens.

- Disadvantages: Not effective on other classes of fires; specialized agents are required.

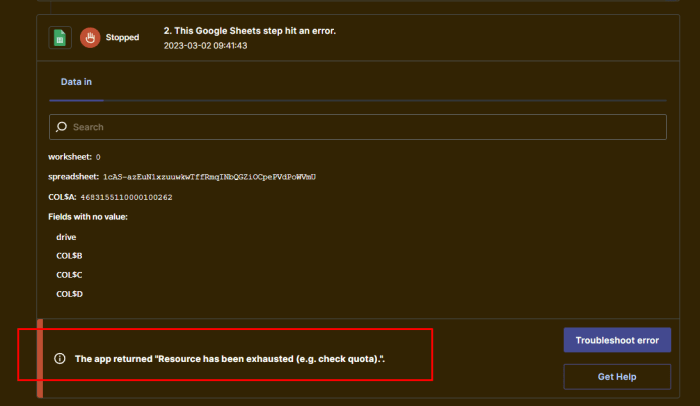

Proper Selection and Placement of Fire Cabinets

Source: sstatic.net

Choosing and placing fire cabinets correctly is crucial for effective fire safety. A poorly chosen or positioned cabinet can render it useless in an emergency, potentially leading to increased property damage and risk to life. This section details the factors to consider for optimal fire cabinet implementation.

Factors Influencing Fire Cabinet Selection

Selecting the right fire cabinet involves careful consideration of several key factors. The type of fire extinguisher housed within the cabinet dictates the cabinet’s design and material requirements. For example, a cabinet storing a Class A extinguisher (for wood, paper, and cloth fires) might have different construction specifications than one holding a Class B extinguisher (for flammable liquids) or a Class K extinguisher (for cooking oils and fats). Environmental factors, such as humidity and temperature extremes, also influence the cabinet’s material selection. Durable, weather-resistant materials are essential for outdoor or harsh-environment placements. Finally, cabinet size must accommodate the extinguisher(s) and allow for easy access and removal. Consider future expansion needs – it’s better to select a slightly larger cabinet than to risk overcrowding.

Guidelines for Proper Fire Cabinet Placement

Strategic placement ensures quick and easy access during emergencies. Fire cabinets should be highly visible, clearly marked, and readily accessible to personnel. Avoid placing them in obstructed areas, behind obstacles, or in locations prone to flooding or other hazards. Ideal placement considers proximity to potential fire hazards and employee traffic patterns, balancing accessibility with the need to prevent accidental damage or interference with the cabinet. Remember, the closer the cabinet is to a potential fire source, the faster a response can be initiated. Placement should also account for the ease of extinguisher removal and deployment; there should be ample space around the cabinet to maneuver.

Material Type and Quantity Considerations

The type and quantity of materials stored in the vicinity directly influence the selection of fire extinguishers and, consequently, the fire cabinet. A warehouse storing large quantities of flammable liquids will require a larger capacity cabinet containing appropriate extinguishers, likely Class B, potentially in greater numbers. An office environment, however, may require smaller cabinets with Class A and potentially Class C extinguishers (for electrical fires). Always conduct a thorough risk assessment to determine the appropriate type and number of extinguishers, and select a cabinet that can safely and effectively house them.

Fire Cabinet Location Suitability Checklist

Before installing a fire cabinet, a thorough evaluation of the proposed location is essential. Use the following checklist to ensure suitability:

- Is the location clearly visible and easily accessible to all personnel?

- Is the area free from obstructions that could hinder access to the cabinet?

- Is the location protected from the elements (e.g., rain, extreme temperatures)?

- Is the floor level and stable, ensuring the cabinet remains upright?

- Is there sufficient space around the cabinet to allow for easy extinguisher removal and use?

- Is the location away from potential hazards, such as heat sources or flammable materials (except for the intended protected area)?

- Is the location compliant with all relevant OSHA regulations and company fire safety policies?

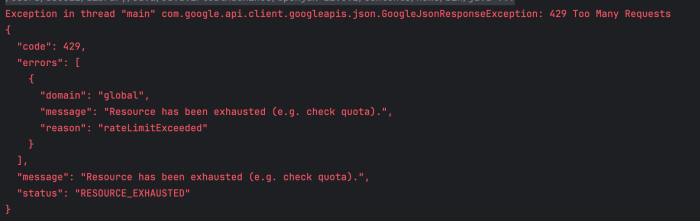

Fire Cabinet Maintenance and Inspection

Source: massivepeak.com

Regular maintenance and inspection of your fire cabinets are crucial for ensuring they’re ready to perform their life-saving function when needed. Neglecting this can lead to malfunctioning equipment, putting your employees and property at risk. A proactive approach to maintenance minimizes these risks and extends the lifespan of your fire cabinets.

A comprehensive maintenance program includes regular inspections, cleaning, and addressing any damage promptly. This involves more than just a quick visual check; it requires a systematic approach to ensure every component is functioning correctly.

Regular Maintenance Schedule, Fire cabinets Osha

Establishing a regular maintenance schedule is key. This schedule should be documented and followed diligently. A good starting point is monthly inspections, with more thorough annual inspections and maintenance. The frequency may need adjusting based on usage, environmental conditions (e.g., exposure to dust, and moisture), and the type of fire extinguisher housed within the cabinet.

- Monthly Inspection: Visually inspect the cabinet for damage, corrosion, loose parts, and obstructions. Check the extinguisher pressure gauge to ensure it’s within the acceptable range. Verify the cabinet door is securely closed and latched. Note any unusual wear and tear.

- Annual Inspection and Maintenance: This should include a more thorough examination. Check all seals and gaskets for wear and tear. Inspect the extinguisher for any signs of damage or corrosion. Ensure the extinguisher’s operating instructions are visible and legible. Consider having a professional service technician inspect and test the extinguisher.

Cleaning and Inspecting Fire Cabinets

Cleaning and inspecting go hand-in-hand. Regular cleaning prevents the accumulation of dust, debris, and corrosive materials that can damage the cabinet and its contents. This also ensures the extinguisher remains easily accessible in an emergency.

- Cleaning Procedure: Use a soft cloth and mild detergent to clean the cabinet’s exterior. Avoid abrasive cleaners or solvents that could damage the cabinet’s finish. Pay close attention to hinges, latches, and other moving parts.

- Inspection Procedure: After cleaning, thoroughly inspect the cabinet for any signs of damage, including dents, cracks, rust, or corrosion. Check the door’s hinges and latch for proper operation. Ensure the cabinet is securely mounted to the wall or other designated location.

Addressing Damage or Deterioration

Promptly addressing any damage or deterioration is vital. Ignoring minor issues can lead to more significant problems and potentially render the cabinet unusable in an emergency.

- Minor Damage: For minor damage like scratches or small dents, cleaning and applying a protective coating may suffice. However, if the structural integrity of the cabinet is compromised, replacement is necessary.

- Significant Damage: Significant damage such as severe corrosion, broken latches, or a damaged door requires immediate attention. The cabinet should be removed from service and replaced. Never use a damaged fire cabinet.

Documenting Inspections and Maintenance

Maintaining accurate records of all inspections and maintenance activities is essential for compliance and accountability. This documentation serves as proof that the fire cabinets are being properly maintained and helps track any issues that may arise.

- Inspection Checklist: Use a standardized checklist to ensure all aspects of the inspection are covered. This checklist should include details about the cabinet’s condition, extinguisher pressure, and any maintenance performed.

- Record Keeping: Keep detailed records of all inspections, maintenance activities, and any repairs or replacements. These records should include the date of the inspection, the inspector’s name, and a description of the cabinet’s condition. Consider using a digital system for easier record-keeping and accessibility.

Emergency Procedures Related to Fire Cabinets

Source: githubusercontent.com

Fire cabinets, while designed to help combat fires, can themselves become involved in or be near a fire. Knowing how to react safely and efficiently in such situations is crucial for minimizing damage and ensuring everyone’s safety. This section details the steps to take in a fire emergency involving or near a fire cabinet.

Procedures in Case of Fire Near or Involving a Fire Cabinet

If a fire breaks out near or involves a fire cabinet, your immediate priority is to ensure the safety of yourself and others. Never attempt to fight a fire beyond your training and the capabilities of the available extinguisher. Your safety is paramount. Remember, a fire extinguisher is only for small, contained fires; if the fire is spreading rapidly or is large, evacuation is the priority.

Safe Evacuation Procedures

Before any emergency, familiarize yourself with the location of fire exits and assembly points. In the event of a fire near a fire cabinet:

- Activate the nearest fire alarm: This alerts others to the emergency and initiates the building’s emergency response plan.

- Evacuate immediately: Do not attempt to retrieve personal belongings. Move quickly and calmly to the nearest designated fire exit.

- Follow evacuation routes: Stay calm and follow the pre-determined evacuation routes. Do not use elevators.

- Account for others: If possible, assist colleagues or others in evacuating, especially those who may need help.

- Assemble at the designated area: Once outside, proceed to the designated assembly point to ensure everyone is accounted for.

It’s important to practice evacuation drills regularly to ensure everyone is familiar with the procedures. This reduces panic and confusion during a real emergency.

Reporting Fire Incidents

Prompt reporting is critical for effective fire response. After evacuating, immediately report the incident to the appropriate authorities:

- Call emergency services: Dial your local emergency number (e.g., 911 in the US) to report the fire and its location.

- Inform your supervisor or designated personnel: Report the incident to your supervisor or other designated personnel within your organization, providing details about the fire’s location, size, and any observed damage.

- Document the incident: After the emergency, document the incident, including the time, location, extent of damage, and actions taken. This information is crucial for investigations and future safety improvements.

Accurate and timely reporting allows for a swift and efficient response, minimizing potential damage and risks.

Emergency Response Flowchart

[A detailed description of a flowchart is provided below, as image links are not permitted.]

The flowchart would begin with a “Fire Detected Near/Involving Fire Cabinet?” decision box. A “Yes” branch would lead to two parallel processes: “Activate Fire Alarm” and “Initiate Evacuation.” Both processes would converge at a “Safe Evacuation Complete?” decision box. A “Yes” branch would lead to “Report Incident to Emergency Services” and “Report Incident to Supervisor/Designated Personnel.” A “No” branch would loop back to “Initiate Evacuation,” emphasizing the priority of safe evacuation. The “Report Incident to Emergency Services” and “Report Incident to Supervisor/Designated Personnel” processes would each lead to an “Incident Reported”endpoint. A “No” branch from the initial decision box (“Fire Detected Near/Involving Fire Cabinet?”) would lead to a “Continue Normal Operations” endpoint

Fire Cabinet Labeling and Signage

Proper labeling and signage on fire cabinets are crucial for workplace safety. Clear and easily understood markings ensure that employees can quickly and correctly identify the type of extinguisher inside, its intended use, and how to operate it in an emergency. This section details OSHA’s requirements and best practices for fire cabinet labeling and signage.

OSHA doesn’t have specific regulations dictating the exact wording or format of fire cabinet labels, but they strongly emphasize the importance of clear and unambiguous labeling as part of their overall fire safety requirements (29 CFR 1910 Subpart L). These regulations mandate that all fire protection equipment be readily accessible and in good working order. Effective labeling contributes directly to this goal. The key is ensuring that labels are visible, legible, and easily understood by all personnel, regardless of language or literacy level.

Labeling Requirements for Different Fire Extinguisher Types

Fire cabinets containing different classes of fire extinguishers require specific labels to indicate their intended use. Labels should clarify the type of fire the extinguisher is designed to combat (Class A, B, C, D, K). For example, a cabinet containing a Class A extinguisher for ordinary combustibles would have a label clearly stating “CLASS A FIRE EXTINGUISHER – ORDINARY COMBUSTIBLES (WOOD, PAPER, CLOTH)”. A cabinet with a Class B extinguisher for flammable liquids would be labeled “CLASS B FIRE EXTINGUISHER – FLAMMABLE LIQUIDS (GASOLINE, OIL)”. A cabinet containing a multi-purpose extinguisher might have a label indicating “CLASS ABC FIRE EXTINGUISHER – ORDINARY COMBUSTIBLES, FLAMMABLE LIQUIDS, AND ELECTRICAL FIRES”. Symbols alongside text are often used to quickly communicate the extinguisher type. For example, a triangle for Class A, a square for Class B, a circle for Class C, and so on.

Signage for Fire Cabinet Location and Accessibility

In addition to individual extinguisher labels, clear signage indicating the location of fire cabinets is essential. These signs should be easily visible from a distance and use universally understood symbols, such as a red square with a white silhouette of a fire extinguisher. The sign should indicate “FIRE EXTINGUISHER” and possibly the cabinet’s contents (“CLASS ABC FIRE EXTINGUISHERS”). The placement of signage should consider sightlines and potential obstructions. Consider using illuminated signs in areas with low lighting. Arrows pointing to the cabinet’s location can further improve visibility. If the cabinet requires a key, the location of the key should be indicated on a nearby sign.

Importance of Clear and Visible Labeling for Safe Handling and Emergency Response

Clear, consistent, and highly visible labeling is critical for safe handling and effective emergency response. In a fire emergency, seconds count. Ambiguous or illegible labels can lead to confusion and delay in using the correct extinguisher, potentially worsening the situation. Clear labeling ensures that everyone, from trained personnel to untrained employees, can quickly identify the appropriate extinguisher and use it effectively. This minimizes property damage and reduces the risk of injury or fatality. Regular inspection of labels to ensure they remain legible and undamaged is vital for maintaining workplace safety.

Summary

Proper fire cabinet management isn’t just about avoiding hefty OSHA fines; it’s about fostering a safe and productive work environment. By understanding OSHA regulations, selecting the appropriate cabinets, and implementing a robust maintenance and emergency plan, you significantly reduce the risk of fire-related incidents and protect your employees. Remember, a proactive approach to fire safety is an investment in peace of mind and a safer workplace for everyone.

Answers to Common Questions

What happens if I don’t comply with OSHA fire cabinet regulations?

OSHA can issue fines, ranging from several hundred to thousands of dollars, depending on the severity of the violation. They may also issue citations and require corrective actions.

Can I use a fire cabinet for all types of flammable materials?

No. Different fire cabinets are rated for different classes of flammable materials (Class A, B, C, etc.). You must choose a cabinet appropriate for the specific materials you’re storing.

How often should I inspect my fire cabinets?

OSHA doesn’t specify an exact frequency, but regular inspections (at least annually, or more frequently depending on usage and material stored) are recommended to identify any damage or deterioration.

What should I do if a fire occurs near a fire cabinet?

Evacuate the area immediately, call emergency services, and follow your company’s fire emergency procedures. Do not attempt to extinguish the fire yourself unless you are trained to do so.

Where can I find more detailed information on OSHA fire cabinet regulations?

Consult the official OSHA website (osha.gov) for the most up-to-date and comprehensive information on fire safety regulations.

Comments are closed.