OSHA 1910.157 Powered Industrial Truck Safety

OSHA 1910.157 covers the safe operation of powered industrial trucks, like forklifts. This standard isn’t just about avoiding accidents; it’s about ensuring a productive and healthy work environment. Understanding its requirements—from training and maintenance to safe operating procedures and PPE—is crucial for any workplace using these powerful machines. Non-compliance can lead to serious injuries and hefty fines, making thorough understanding a top priority.

This guide breaks down the key aspects of OSHA 1910.157, providing a practical overview of training needs, inspection procedures, maintenance best practices, and safe operating guidelines. We’ll explore common hazards and how to mitigate them, emphasizing the importance of both operator skill and proper equipment upkeep. By the end, you’ll have a clear understanding of how to comply with this vital safety standard.

Overview of OSHA 1910.157 (Powered Industrial Trucks)

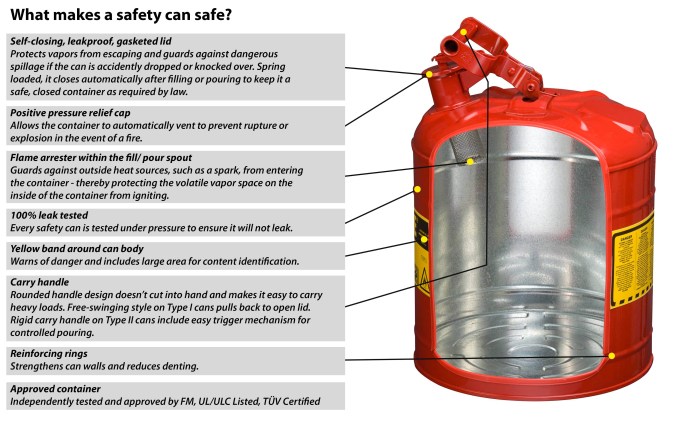

Source: justrite.com

OSHA 1910.157, “Powered industrial trucks,” is a crucial standard designed to protect workers from hazards associated with the operation, maintenance, and use of these vehicles. It aims to minimize workplace accidents and injuries related to powered industrial trucks, a common piece of equipment in many industries. This standard covers a wide range of trucks and addresses key areas like training, inspection, and maintenance.

Types of Powered Industrial Trucks Covered

This standard covers a broad spectrum of powered industrial trucks, including forklifts, platform lift trucks, motorized hand trucks, tractors, and similar equipment used for materials handling. Specific examples include electric forklifts, propane-powered forklifts, and even specialized trucks designed for specific tasks or industries. The standard doesn’t cover hand trucks or other non-powered equipment. The key is whether the truck is powered by an engine or battery.

Training Requirements

Proper training is paramount to safe operation. OSHA 1910.157 mandates that all operators receive adequate training before operating any powered industrial truck. This training must cover pre-operation inspection procedures, safe operating procedures, and potential hazards associated with the specific type of truck being operated. Refresher training is also required periodically to ensure ongoing competency and awareness of safety protocols. The training must be documented.

Inspection and Maintenance Requirements

Regular inspections and preventative maintenance are vital to preventing accidents. The standard Artikels the frequency and scope of these inspections, emphasizing the need to check for mechanical defects, fluid leaks, and any other issues that could compromise the safe operation of the truck. Maintenance should be performed by qualified personnel and records of these activities should be kept. Ignoring these requirements significantly increases the risk of accidents and breakdowns.

Key Requirements and Penalties

| Section Number | Topic | Key Requirements | Penalties for Non-Compliance |

|---|---|---|---|

| 1910.157(a)(1) | General Requirements | Compliance with all aspects of the standard. | Citations and penalties vary depending on the severity and nature of the violation, potentially including fines and corrective action orders. |

| 1910.157(b) | Definitions | Understanding the specific definitions of terms used throughout the standard. | Same as above; failure to understand definitions can lead to improper implementation of the standard. |

| 1910.157(c) | Training | Comprehensive training for operators, covering pre-operation inspection, safe operation, and hazard recognition. | Significant fines and potential for further action if accidents occur due to inadequate training. |

| 1910.157(d) | Inspection | Regular inspection of trucks before each use. | Fines for failing to conduct proper inspections leading to unsafe operation. |

| 1910.157(e) | Maintenance | Regular maintenance to ensure safe operation. | Fines and potential for further action if accidents occur due to improper maintenance. |

| 1910.157(f) | Safe Operating Practices | Following established safe operating procedures. | Fines for unsafe practices leading to accidents or near misses. |

Training Requirements under OSHA 1910.157

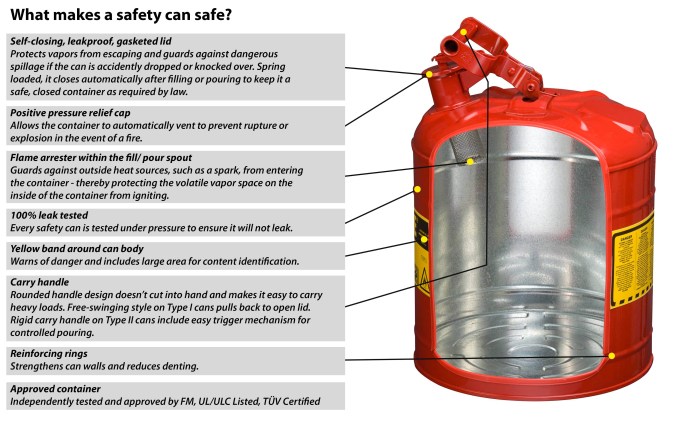

Source: safesitehq.com

OSHA 1910.157 mandates comprehensive training for all powered industrial truck operators. This training isn’t a one-size-fits-all approach; it’s tailored to the specific type of equipment and the operator’s experience level. Failure to provide adequate training can lead to serious accidents and hefty fines.

Types of Training for Powered Industrial Truck Operators

OSHA 1910.157 doesn’t specify a rigid curriculum, but it Artikels essential elements. Training must cover safe operating procedures, pre-operation checks, potential hazards, and emergency response. The specific content will vary depending on the type of truck (forklifts, order pickers, pallet jacks, etc.). For example, training for forklift operators will heavily emphasize load stability and maneuvering in confined spaces, while training for order pickers will focus on safe platform operation and high-reach procedures. The training must also address the specific workplace environment, including potential obstacles and hazards unique to the facility.

Sample Training Program Meeting OSHA 1910.157 Requirements

A comprehensive training program should include the following phases:

- Classroom Instruction: This phase covers theoretical aspects like truck operation principles, pre-operational checks, safe load handling techniques, and hazard recognition. It also includes instruction on relevant OSHA standards and company safety policies. The use of visual aids like diagrams, videos, and interactive presentations are recommended.

- Practical Training: This involves hands-on experience operating a specific type of powered industrial truck under the supervision of a qualified trainer. Operators practice pre-operation checks, maneuvering, load handling, and emergency procedures in a controlled environment. This phase allows for immediate feedback and correction of unsafe practices.

- Evaluation: A written test assessing knowledge of safe operating procedures and a practical driving test demonstrating proficiency in operating the truck is crucial. These evaluations ensure operators have absorbed the training and can safely operate the equipment.

- Refresher Training: Periodic refresher training is necessary to reinforce safe operating practices and address any changes in equipment, procedures, or regulations. The frequency of refresher training will depend on factors like the operator’s performance and the complexity of the work environment.

Training Requirements for Experienced vs. Inexperienced Operators

Inexperienced operators require comprehensive initial training encompassing all aspects of safe operation. Experienced operators, while already possessing some knowledge, still need refresher training to address new equipment, updated procedures, and changes in regulations. Refresher training for experienced operators may focus on specific areas needing improvement or new safety protocols. Both groups need to demonstrate competency through written and practical tests.

Effective Training Methods and Materials

Effective training utilizes a variety of methods to cater to different learning styles. These include:

- Interactive simulations: These allow operators to practice in a risk-free environment, experiencing different scenarios and learning from mistakes without real-world consequences.

- Videos and presentations: These provide clear visual demonstrations of proper operating techniques and potential hazards.

- Hands-on training: Practical experience is crucial for developing proficiency and building muscle memory for safe operation.

- Case studies: Analyzing real-world accidents helps operators understand the consequences of unsafe practices and learn from others’ mistakes.

- Checklists and workbooks: These provide a structured approach to pre-operation checks and reinforce safe operating procedures.

Inspection and Maintenance Procedures

Keeping your powered industrial trucks (PITs) in top shape is crucial for safety. Regular inspections and preventative maintenance are not just good ppractices they’re legally mandated under OSHA 1910.157. Neglecting these procedures significantly increases the risk of accidents, injuries, and costly downtime. This section details the necessary steps to ensure your PITs are always ready for safe operation.

Pre-Operational Inspection Checklist, Osha 1910.157

Before each use, a thorough pre-operational inspection is vital. This inspection should identify any potential hazards before they lead to accidents. Failing to perform this check could expose workers to serious risks. The following checklist should be used:

- Tires: Check tire pressure and condition for wear, cuts, or damage. Ensure proper inflation to prevent punctures and maintain stability.

- Brakes: Test brake functionality. Listen for unusual noises or feel for spongy brakes, indicating potential issues.

- Steering: Check steering responsiveness and for any binding or unusual play.

- Lights and Signals: Verify that all lights (headlights, brake lights, turn signals) and warning devices are working correctly.

- Horn: Test the horn to ensure it functions properly.

- Fluid Levels: Check engine oil, transmission fluid, and hydraulic fluid levels. Low levels indicate leaks that require immediate attention.

- Leaks: Inspect for any leaks of fluids, such as oil, fuel, or hydraulic fluid. Leaks can cause fires or environmental hazards.

- Mast and Forks: Inspect the mast for damage, cracks, or bends. Check the forks for damage, alignment, and proper functionality.

- Safety Devices: Confirm that all safety devices, such as seatbelts, backup alarms, and overhead guards, are in place and functioning correctly.

- Overall Condition: Conduct a visual inspection for any signs of damage or wear, including loose bolts, frayed wires, or damaged components.

Post-Operational Inspection Checklist

After each use, a post-operational inspection is equally important. This helps to identify any issues that may have arisen during operation and prevents them from becoming more serious problems. The following checklist should be completed:

- Fuel Level: Note the fuel level to monitor consumption and plan refueling.

- Damage Assessment: Check for any new damage to the truck or its components.

- Cleanliness: Remove any debris or material from the truck, particularly from the engine compartment and moving parts.

- Securement: Ensure the truck is parked securely and in a designated area.

Regular Maintenance Procedures

Regular maintenance extends the lifespan of your PITs and minimizes the risk of breakdowns and accidents. A preventative maintenance schedule, tailored to the specific type and usage of your PITs, should be implemented. This includes:

- Scheduled Inspections: Conduct more in-depth inspections at regular intervals (e.g., weekly, monthly) covering all components and systems.

- Lubrication: Regular lubrication of moving parts is essential to prevent wear and tear.

- Fluid Changes: Change engine oil, transmission fluid, and hydraulic fluid according to the manufacturer’s recommendations.

- Tire Rotation and Replacement: Rotate tires regularly to ensure even wear and replace worn or damaged tires promptly.

- Battery Maintenance (for electric PITs): Regularly check battery water levels, charge the battery correctly, and clean battery terminals.

- Component Replacements: Replace worn or damaged components promptly, following manufacturer specifications.

Common Maintenance Issues and Solutions

Identifying and addressing common maintenance issues promptly is crucial. Here are a few examples:

- Problem: Spongy brakes. Solution: Inspect brake pads and lines for wear or leaks. Bleeding the brake system may be necessary.

- Problem: Steering wheel play. Solution: Check steering components for wear or damage. Tighten loose connections or replace worn parts.

- Problem: Fluid leaks. Solution: Identify the source of the leak and repair or replace the damaged component. This often requires professional attention.

- Problem: Malfunctioning lights. Solution: Check bulbs, wiring, and fuses. Replace faulty components.

Safe Operating Procedures

Operating powered industrial trucks safely requires a comprehensive understanding of potential hazards and adherence to established procedures. Ignoring safety protocols can lead to serious accidents, injuries, and property damage. This section Identifies key aspects of safe operation, emphasizing preventative measures and best practices.

Common Hazards Associated with Powered Industrial Truck Operation

Numerous hazards are inherent in operating powered industrial trucks. These include collisions with other vehicles, pedestrians, or fixed objects; tipping over due to uneven terrain or excessive speed; being struck by falling objects; exposure to hazardous materials; and equipment malfunctions. Furthermore, improper loading and securing of cargo can lead to instability and accidents. Environmental factors like poor visibility due to weather or inadequate lighting also significantly increase risk.

Safe Operating Procedures for Various Environments and Conditions

Operating in different environments requires adapting procedures to minimize risks. On inclines, for example, operators should proceed slowly, maintaining a low center of gravity, and avoiding sharp turns. In confined spaces, maneuverability is limited, necessitating extra caution and awareness of surroundings. Operators must be trained to assess the space before entering and operate at reduced speeds. Operating in areas with poor visibility requires using additional safety measures, such as backup alarms and spotters, and slowing down significantly. Wet or icy conditions demand even greater caution, with reduced speeds and increased braking distances being crucial.

Best Practices for Preventing Accidents

Preventing accidents relies on a multi-faceted approach. Regular pre-operation inspections are paramount, checking for tire pressure, fluid levels, and any visible damage. Ensuring the load is properly secured and balanced is crucial to prevent tipping. Maintaining a safe operating speed, appropriate for the conditions and environment, is essential. Operators should always be aware of their surroundings, anticipating potential hazards and adjusting their operation accordingly. Effective communication, especially in busy environments, is critical to avoid collisions. This might involve the use of hand signals, horns, or communication systems.

Traffic Rules and Pedestrian Safety Guidelines

Following traffic rules and prioritizing pedestrian safety are non-negotiable. Operators must yield to pedestrians and other vehicles, following established traffic patterns and speed limits within the facility. Designated pedestrian walkways should be respected and kept clear of truck traffic. Using appropriate warning signals, such as horns or backup alarms, can significantly reduce the risk of collisions with pedestrians. Establishing clear communication channels between pedestrians and truck operators is crucial in high-traffic areas. Designated pedestrian crossing areas and clear signage help to improve safety.

Personal Protective Equipment (PPE)

Source: eurekaoxygencompany.com

Operating powered industrial trucks, like forklifts, presents inherent risks. Protecting yourself from these hazards is paramount, and the right Personal Protective Equipment (PPE) plays a crucial role in ensuring your safety and the safety of others. Choosing, using, and maintaining PPE correctly is not just a matter of compliance; it’s a matter of life and death.

Appropriate PPE significantly reduces the risk of serious injuries. Consistent and proper use of PPE is essential, and regular inspection and maintenance are equally important to ensure their effectiveness. Failing to do so compromises the protection they offer and increases the likelihood of accidents.

Types of PPE for Powered Industrial Truck Operation

Several types of PPE are essential when operating powered industrial trucks. These items work together to safeguard various parts of your body from different potential hazards.

- Safety Glasses or Goggles: Protect your eyes from flying debris, dust, and chemical splashes. Consider impact-resistant safety glasses that meet ANSI Z87.1 standards.

- Hearing Protection: Forklifts can generate significant noise levels. Ear plugs or muffs are necessary to prevent hearing damage from prolonged exposure. Choose a hearing protector with a Noise Reduction Rating (NRR) appropriate for the noise levels in your work environment.

- Gloves: Appropriate gloves offer protection against cuts, abrasions, and chemical exposure. The type of glove needed depends on the specific tasks and materials handled. For example, work gloves with good grip are necessary for handling loads.

- Steel-Toed Boots: These protect your feet from falling objects, crushing injuries, and punctures. Ensure your boots meet ANSI Z41 standards for safety footwear.

- High-Visibility Clothing: In areas with other vehicles or pedestrians, high-visibility vests or clothing significantly improve your visibility, reducing the risk of collisions.

Importance of PPE Use and Maintenance

Regularly inspecting and maintaining your PPE is crucial. Damaged or worn-out PPE offers significantly reduced protection and should be replaced immediately. Clean and store your PPE correctly to prolong its lifespan and maintain its effectiveness. For example, gloves should be cleaned after each use, and safety glasses should be stored in a protective case to prevent scratches. Training on proper PPE use and maintenance is vital to ensure workers understand their responsibilities and how to effectively utilize these safety measures.

Example of a Worker Correctly Using PPE

Imagine a worker operating a forklift. They are wearing steel-toed boots, high-visibility vests, safety glasses, and hearing protection. Their gloves are clean and in good condition. They are carefully maneuvering the forklift, maintaining a safe speed and distance from other workers and obstacles. Their overall appearance demonstrates a commitment to safety and a proper understanding of PPE usage. The worker is attentively focused on their task and surroundings, showing responsible operation.

Recordkeeping and Reporting Requirements

Source: slideserve.com

OSHA 1910.157 mandates comprehensive recordkeeping and reporting to ensure accountability and continuous improvement in powered industrial truck safety. Maintaining accurate records allows employers to track training effectiveness, identify potential hazards, and demonstrate compliance with regulations. Thorough reporting of accidents helps prevent future incidents.

Proper recordkeeping and reporting are crucial for demonstrating compliance with OSHA 1910.157. Failure to maintain adequate records or promptly report accidents can result in citations and penalties. This sectionArticulatess the requirements for maintaining records of training, inspections, and accidents, as well as the procedures for reporting incidents.

Training Records

Maintaining detailed training records is essential. These records should demonstrate that each operator has received the necessary training and is competent to operate the specific type of powered industrial truck. This includes the date of training, the type of training received (initial, refresher, etc.), the trainer’s name and qualifications, and the operator’s name and employee ID. Records should also document any evaluations or tests conducted to assess operator competency.

Inspection and Maintenance Records

Regular inspections and maintenance are critical for preventing accidents. Records of these activities should include the date of the inspection or maintenance, the type of inspection (pre-operational, periodic, etc.), the name of the person who performed the inspection or maintenance, and a description of any repairs or adjustments made. Any deficiencies identified during inspections should be documented, along with the corrective actions taken.

Accident and Injury Reports

Accidents involving powered industrial trucks must be reported promptly to OSHA and documented thoroughly. The employer must maintain a record of each accident, including the date, time, and location of the accident; a description of the accident; the names and employee IDs of any injured persons; a description of the injuries sustained; the type of powered industrial truck involved; and the contributing factors to the accident.

Sample Recordkeeping System

- Employee Training Records: A file or database containing individual records for each operator, including training dates, type of training, trainer information, and competency evaluation results.

- Equipment Inspection Records: A logbook or spreadsheet documenting each inspection, including the date, inspector’s name, equipment ID, and details of any repairs or maintenance performed.

- Accident/Incident Reports: A standardized form to record the details of any accident or near miss involving a powered industrial truck, including witness statements and photographs (if available).

Accident Report Information Examples

Accident reports should include comprehensive details to facilitate thorough investigation and preventative measures. Examples of information to include are:

- Date, Time, and Location: Precise details of when and where the accident occurred.

- Description of the Accident: A clear and concise narrative of the events leading to the accident.

- Personnel Involved: Names, employee IDs, and injuries sustained by all individuals involved.

- Equipment Involved: Type of powered industrial truck, its identification number, and its condition before the accident.

- Contributing Factors: Details about environmental conditions, operator error, equipment malfunction, or other factors contributing to the accident.

- Witnesses: Names and contact information of any witnesses to the accident.

- Corrective Actions: Steps taken to prevent similar accidents from occurring in the future.

Closure

Mastering OSHA 1910.157 isn’t just about ticking boxes; it’s about fostering a culture of safety. By implementing robust training programs, consistent inspection and maintenance routines, and a commitment to safe operating procedures, workplaces can significantly reduce the risk of accidents involving powered industrial trucks. Remember, a proactive approach to safety is the best investment you can make – protecting your workers and your business’s bottom line.

FAQ

What are the penalties for non-compliance with OSHA 1910.157?

Penalties vary depending on the severity of the violation but can range from warnings and fines to complete work stoppages.

How often should powered industrial trucks be inspected?

OSHA recommends daily pre-operational inspections, plus regular scheduled maintenance based on manufacturer recommendations and usage.

Can I use mytrainingg program, or must I use a specific OSHA-approved one?

You can create your training program, but it must cover all the requirements articulated in OSHA 1910.157.

What if an accident occurs? What’s the reporting procedure?

Accidents must be reported according to your company’s and OSHA’s guidelines, typically involving immediate first aid, incident reporting forms, and potentially contacting OSHA directly depending on the severity.

Are there specific requirements for operating powered industrial trucks in different environments (e.g., outdoor, warehouse)?

Yes, operating procedures should be adapted to account for environmental factors like weather conditions, uneven terrain, and potential obstacles. Additional training may be necessary for specific environments.

Comments are closed.