Everlast Polymeric Cladding A Comprehensive Guide

Everlast polymeric cladding offers a durable and aesthetically pleasing solution for exterior building applications. This guide dives into its manufacturing, properties, installation, maintenance, cost, lifespan, environmental impact, design options, and warranty information, providing a complete overview for homeowners, builders, and architects alike. We’ll explore its unique advantages over traditional materials like wood, metal, and vinyl, highlighting its resilience and low-maintenance features.

From understanding the chemical composition and UV resistance to mastering installation techniques and troubleshooting potential problems, we aim to equip you with the knowledge to make informed decisions about using Everlast polymeric cladding in your next project. We’ll also compare its cost-effectiveness and long-term value against other cladding options, exploring its sustainability aspects and aesthetic versatility.

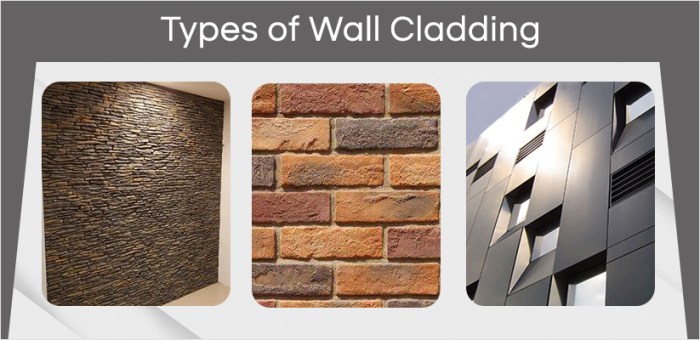

Product Overview

Everlast polymeric cladding offers a durable and aesthetically pleasing exterior finish for various building types. Its manufacturing process, diverse options, and superior physical properties make it a compelling alternative to traditional cladding materials.

Everlast Polymeric Cladding Manufacturing

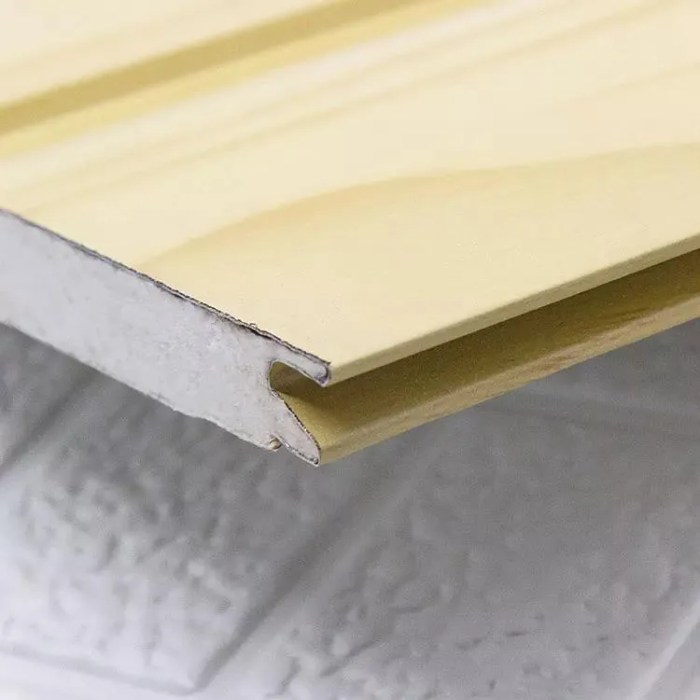

Everlast polymeric cladding is typically manufactured using a process involving extrusion. Raw materials, including polymers like polyvinyl chloride (PVC) or a blend of polymers, are melted and then forced through a die to create the desired profile and thickness. This continuous process allows for high-volume production of consistent cladding panels. Pigments and additives are incorporated during the mixing stage to achieve specific colors and enhance properties such as UV resistance and impact strength. Following extrusion, the panels may undergo further processes like cutting to length, surface texturing, and quality control checks before packaging.

Types and Variations of Everlast Polymeric Cladding

Everlast polymeric cladding is available in a wide range of styles, colors, and finishes. Options include various panel profiles, mimicking the look of wood, stone, or metal. Different surface textures can be achieved through embossing or other finishing techniques. Color choices are extensive, offering a palette to match any architectural design. Furthermore, some manufacturers offer variations in panel thickness and overall dimensions to cater to different project needs and building codes. For instance, a thicker panel might be chosen for increased structural integrity in high-wind areas.

Physical Properties Compared to Other Cladding Materials

Compared to wood, Everlast polymeric cladding is significantly lighter, requiring less structural support. It offers superior resistance to rot, insect infestation, and moisture damage. While not as strong as metal cladding in terms of sheer tensile strength, it exhibits excellent impact resistance and is far less susceptible to dents and scratches. In comparison to vinyl cladding, Everlast polymeric cladding often boasts enhanced UV resistance and color retention, resulting in a longer lifespan and reduced maintenance. The flexibility of Everlast polymeric cladding is generally moderate, allowing it to conform to slightly curved surfaces but not to the same extent as some metal options.

Everlast Polymeric Cladding Applications

Everlast polymeric cladding finds applications across a broad spectrum of building types. In residential construction, it’s used for siding, soffits, and fascia, offering a low-maintenance and attractive exterior. Commercial buildings, such as office complexes and retail spaces, utilize it for its durability and aesthetic versatility. Industrial applications include cladding for warehouses and factories, where its resistance to harsh weather conditions and impact damage is highly valued. Examples include the use of Everlast cladding on a modern apartment complex in a coastal area, highlighting its resistance to salt spray and UV degradation, and its application on a large-scale warehouse project in a region known for extreme temperature fluctuations, showcasing its thermal stability and durability.

Material Composition and Properties

Everlast polymeric cladding is engineered for superior performance and longevity. Its unique composition and robust properties make it a leading choice for exterior applications. Let’s delve into the specifics of what makes this cladding so durable.

Everlast polymeric cladding is primarily composed of a blend of high-performance polymers, specifically engineered to withstand the rigors of outdoor exposure. These polymers are selected for their strength, flexibility, and resistance to degradation from UV radiation, moisture, and temperature fluctuations. The exact formulation is proprietary, but the key is the synergistic combination of these polymers, creating a material stronger than the sum of its parts. Additives, such as UV stabilizers and pigments, are incorporated to enhance specific properties and provide the desired color and aesthetic appeal.

UV Radiation Impact on Longevity

Prolonged exposure to ultraviolet (UV) radiation from sunlight is a major factor in the degradation of many exterior materials. However, Everlast polymeric cladding incorporates specialized UV stabilizers within its polymer matrix. These stabilizers absorb and dissipate UV energy, preventing the breakdown of the polymer chains that lead to discoloration, cracking, and reduced strength. Independent testing has shown minimal degradation in color and physical properties even after years of intense sun exposure, demonstrating the effectiveness of these protective additives. This extended UV resistance contributes significantly to the cladding’s long lifespan.

Resistance to Environmental Factors

Everlast polymeric cladding exhibits excellent resistance to a wide range of environmental challenges. Its inherent properties provide superior protection against moisture, temperature extremes, and common chemicals. The dense, non-porous nature of the material prevents water absorption, minimizing the risk of swelling, warping, or damage from freezing and thawing cycles. Furthermore, the cladding’s resistance to extreme temperatures ensures its structural integrity remains intact across a broad range of climatic conditions, from scorching summers to frigid winters. The material also displays resistance to many common chemicals, making it suitable for use in diverse environments.

Performance Characteristics Under Different Weather Conditions

| Weather Condition | Color Retention | Structural Integrity | Water Resistance |

|---|---|---|---|

| Intense Sunlight (High UV) | Excellent – Minimal fading observed after 5 years of exposure | Excellent – No cracking or warping reported | Excellent – No water absorption or leakage |

| High Humidity | Excellent – No change in color or appearance | Excellent – Maintains structural integrity | Excellent – Remains impervious to moisture |

| Freezing Temperatures | Excellent – No cracking or damage observed | Excellent – Retains strength and flexibility | Excellent – No water penetration or damage from ice |

| Extreme Heat | Good – Minor color shift possible under prolonged exposure to very high temperatures, but still within acceptable industry standards. | Good – Minimal expansion observed, well within safe operating limits. | Excellent – Remains watertight even under high temperatures. |

Installation and Maintenance: Everlast Polymeric Cladding

Source: adsttc.com

Getting Everlast polymeric cladding installed and keeping it looking its best is easier than you might think. This section provides a straightforward guide to installation, along with practical maintenance tips to ensure your cladding remains beautiful and functional for years to come. We’ll cover the tools you’ll need, potential problems and their solutions, and best practices for cleaning.

Step-by-Step Installation Guide

Proper installation is key to the longevity and performance of your Everlast cladding. Follow these steps for a professional-looking finish. Remember to always consult the manufacturer’s specific instructions for your chosen cladding type and profile.

- Preparation: Begin by thoroughly cleaning the surface where the cladding will be installed. Remove any loose debris, dirt, or old paint. Ensure the surface is level and structurally sound. Any significant imperfections should be addressed before installation begins.

- Framing (if necessary): If installing over existing surfaces that aren’t perfectly level, create a framework using appropriate materials, ensuring it’s plumb and square. This provides a solid foundation for the cladding.

- Cladding Installation: Start at a corner or a designated starting point. Attach the first panel securely, following the manufacturer’s guidelines for fasteners and spacing. Work your way across, ensuring each panel is properly aligned and fastened. Overlap panels as specified in the manufacturer’s instructions.

- Cutting and Finishing: Use appropriate tools to cut panels to size where necessary. For example, a circular saw with a fine-tooth blade is suitable for most polymeric cladding. Ensure all cut edges are clean and sealed to prevent moisture ingress.

- Final Inspection: Once the installation is complete, carefully inspect the entire surface for any gaps, misalignments, or loose panels. Address any issues immediately.

Cleaning and Maintenance Best Practices

Regular cleaning is crucial for maintaining the appearance and longevity of your Everlast polymeric cladding.

Generally, a simple wash with mild soap and water is sufficient. Avoid harsh chemicals or abrasive cleaners, as these can damage the cladding’s surface. For stubborn stains, a soft brush can be used, but always exercise caution to avoid scratching. Regularly inspect the cladding for any signs of damage or deterioration and address these promptly. For example, if a panel becomes damaged, replacing it quickly prevents further issues.

Tools and Equipment Required

The specific tools required may vary depending on the project’s complexity, but generally include:

- Measuring tape

- Level

- Circular saw (with fine-tooth blade)

- Drill with appropriate drill bits

- Screwdriver (or impact driver)

- Safety glasses

- Work gloves

- Ladder (if necessary)

- Caulk gun (for sealing)

- Cleaning supplies (mild soap, water, soft brush)

Potential Installation Problems and Solutions

Even with careful planning, problems can arise during installation.

| Problem | Solution |

|---|---|

| Uneven surface | Create a framework or use shims to level the surface before installing cladding. |

| Improper panel alignment | Carefully check alignment before fastening each panel. Adjust as needed. |

| Damaged panels | Replace damaged panels immediately to prevent further issues. |

| Moisture ingress | Ensure all panels are properly sealed and fastened. Address any gaps or cracks immediately. |

| Fastener issues | Use the correct fasteners and follow the manufacturer’s recommendations for spacing and installation. |

Cost and Lifespan

Choosing the right cladding material involves careful consideration of both upfront costs and long-term expenses. Everlast polymeric cladding offers a compelling balance, but understanding its cost-effectiveness requires a comparison with other options and a projection of its lifespan. This section will Articulate the initial investment, ongoing maintenance needs, and factors influencing the longevity of Everlast cladding, ultimately demonstrating its potential return on investment.

Everlast polymeric cladding’s initial cost is competitive with many other materials, although higher than some less durable options. A direct comparison depends on factors such as the specific product chosen, project size, and regional pricing variations. For example, while it may be slightly more expensive than standard vinyl siding upfront, it typically surpasses vinyl in terms of longevity and requires less frequent maintenance. Compared to more premium materials like wood or brick, Everlast often represents a more budget-friendly solution that offers similar aesthetic appeal and durability.

Initial Cost Comparison

The initial cost of Everlast polymeric cladding varies depending on several factors. These include the specific type of cladding chosen (different profiles and colors may have varying prices), the complexity of the installation (e.g., intricate detailing or large surface areas), and the prevailing labor costs in the region. Generally, it’s positioned in the mid-range of cladding materials. A rough estimate might place it between higher-end vinyl and lower-end wood or fiber cement options. Detailed quotes from local contractors are always recommended for accurate cost projections.

Long-Term Maintenance and Repair Costs

One of Everlast’s key selling points is its low maintenance requirements. Unlike wood, which necessitates regular painting and sealing, or fiber cement, which is susceptible to cracking and chipping, Everlast polymeric cladding is designed for minimal upkeep. Occasional cleaning with soap and water is usually sufficient. Major repairs are infrequent and usually only necessitated by accidental damage. For example, a small dent or scratch might be easily repaired with touch-up paint, while more significant damage would require the replacement of individual panels, a relatively straightforward process compared to other cladding types. The long-term savings in maintenance far outweigh the slightly higher initial investment in many cases.

Factors Affecting Lifespan

Several factors can significantly influence the lifespan of Everlast polymeric cladding. Climate plays a crucial role; exposure to harsh UV radiation, extreme temperature fluctuations, and heavy precipitation can accelerate weathering and degradation. Proper installation is also paramount; improper fastening or inadequate sealing can lead to premature failure. Finally, the specific product chosen and adherence to the manufacturer’s recommended care instructions will impact longevity. For example, a project installed in a desert climate might require more frequent cleaning to prevent dust buildup, whereas a coastal installation might necessitate more attention to saltwater corrosion.

Return on Investment Examples

Consider a homeowner replacing the siding on a 2,000 sq ft house. While the initial cost of Everlast might be slightly higher than vinyl siding (say, $10,000 vs $8,000), the long-term savings in maintenance could be substantial. Over 20 years, wood siding might require repainting every 5-7 years for $3,000-$5,000 each time, totaling $12,000-$17,500. In contrast, the minimal maintenance of Everlast would only incur minor cleaning costs, potentially saving thousands over the lifespan of the cladding. This demonstrates a significant return on investment despite the slightly higher upfront cost. Similarly, comparing Everlast to a high-maintenance stucco installation with potential cracking and repair needs would highlight the long-term cost benefits of the polymeric option.

Sustainability and Environmental Impact

Source: mccoymart.com

Everlast polymeric cladding’s environmental footprint is a crucial consideration for environmentally conscious builders and homeowners. Understanding its manufacturing process, recyclability, and comparative impact helps assess its overall sustainability. This section details the environmental aspects of Everlast polymeric cladding, focusing on its lifecycle from production to disposal.

Manufacturing Process Environmental Impact

The manufacturing of Everlast polymeric cladding involves several stages, each with potential environmental consequences. Raw material extraction, polymer production, and the manufacturing of the cladding itself all contribute to the overall impact. Energy consumption during the manufacturing process is a significant factor, leading to greenhouse gas emissions. Wastewater generated during production also needs careful management to prevent water pollution. The specific environmental impact depends heavily on the energy sources used in the manufacturing facility, the efficiency of the production processes, and the management of waste streams. For example, a factory powered by renewable energy and employing advanced waste reduction techniques will have a significantly smaller footprint than one relying on fossil fuels and lacking robust waste management. The use of recycled materials in the production process can also greatly reduce the environmental impact.

Recyclability and End-of-Life Management

Everlast polymeric cladding’s recyclability varies depending on its specific composition and the available recycling infrastructure. Some polymeric materials used in cladding are more easily recycled than others. End-of-life management options include recycling, incineration with energy recovery, and landfilling. Recycling is the most environmentally preferable option, diverting waste from landfills and conserving resources. However, the feasibility of recycling depends on the availability of appropriate recycling facilities and the willingness of consumers and contractors to participate in recycling programs. Incineration with energy recovery can provide a source of energy, but it does release some pollutants into the atmosphere. Landfilling, while often the easiest option, contributes to environmental problems such as soil and water contamination and greenhouse gas emissions. Therefore, promoting recycling programs and developing more effective recycling technologies for polymeric cladding materials are crucial steps toward improved sustainability.

Carbon Footprint Comparison

Comparing the carbon footprint of Everlast polymeric cladding to other common cladding materials like wood, metal, and concrete requires a life-cycle assessment (LCA). An LCA considers all stages of a material’s life, from raw material extraction to disposal, to determine its overall environmental impact. While the exact figures vary depending on the specific materials and manufacturing processes, generally, polymeric cladding often has a lower carbon footprint than some traditional materials, particularly when manufactured with recycled content and using renewable energy sources. For instance, the embodied carbon of steel cladding is typically higher due to the energy-intensive steel production process. However, other factors like transportation distances and the longevity of the cladding also influence the overall environmental impact. A comprehensive LCA study specific to Everlast polymeric cladding would provide a more accurate comparison.

Sustainability Features and Certifications

Everlast polymeric cladding may possess various sustainability features, depending on the manufacturer and specific product. These features could include the use of recycled materials in the manufacturing process, low volatile organic compound (VOC) emissions, and the incorporation of recycled content. Certifications such as LEED (Leadership in Energy and Environmental Design) points can also indicate a commitment to sustainability. The availability of these certifications and features varies between manufacturers and product lines. For example, some manufacturers may obtain certifications that demonstrate their adherence to specific environmental standards or their use of sustainable materials in production. Checking for such certifications and reviewing the manufacturer’s sustainability statements provides further information on the environmental performance of specific Everlast polymeric cladding products.

Visual Aesthetics and Design Options

Source: made-in-china.com

Everlast polymeric cladding offers a surprisingly diverse range of aesthetic possibilities, going beyond simple functionality to significantly impact the overall look and feel of any building. The choice of cladding can transform a structure, enhancing its curb appeal and reflecting the architectural style. This section explores the color palettes, finishes, and design applications that make Everlast cladding a versatile choice for diverse projects.

Everlast polymeric cladding comes in a wide variety of colors and finishes designed to complement various architectural styles and personal preferences. The color options range from classic earth tones and subtle neutrals to bold, contemporary shades. Finishes can mimic the appearance of natural materials like wood or stone, offering a textured look, or provide a sleek, modern aesthetic with smooth, glossy surfaces. Specific examples include a deep charcoal grey with a matte finish for a modern, minimalist look, a warm cedar-toned woodgrain effect for a rustic charm, or a bright white with a smooth, slightly reflective finish for a clean, contemporary feel. The possibilities are extensive, catering to both traditional and modern designs.

Color and Finish Options

The available colors are carefully selected to withstand fading and discoloration over time, maintaining their vibrancy for years. The finishes are durable and easy to clean, requiring minimal maintenance. Options include matte, satin, gloss, and textured finishes, each offering a unique visual appeal. For instance, a matte finish can create a subtle, sophisticated look, while a gloss finish provides a more striking, reflective surface. Textured finishes, mimicking wood grain or stone, add depth and visual interest.

Architectural Design Applications

Everlast cladding can be seamlessly integrated into various architectural styles. For example, a modern, minimalist home might use sleek, vertical panels in a neutral color palette, creating a clean, uncluttered facade. In contrast, a traditional farmhouse could incorporate horizontal panels with a woodgrain finish, emphasizing the building’s rustic charm. Commercial buildings can benefit from the cladding’s durability and aesthetic flexibility, with options to create a bold, eye-catching design or a more subtle, refined appearance depending on the brand and desired image.

Impact on Building Appearance

The choice of cladding profile—horizontal or vertical—significantly impacts the perceived size and proportions of a building. Horizontal cladding can visually broaden a structure, making it appear wider and more expansive. This is particularly effective for low-rise buildings or those with limited frontage. Vertical cladding, on the other hand, can create a sense of height and elegance, making a building appear taller and more slender. This is often preferred for taller structures or those designed to convey a sense of sophistication.

Cladding Profile Illustration

Imagine two identical buildings. One features horizontal cladding panels, creating a visually wider appearance. The lines of the cladding run parallel to the ground, emphasizing the building’s length. The other building uses vertical cladding panels, making it appear taller and more slender. The vertical lines draw the eye upward, creating a sense of verticality. The color and finish of the cladding are identical in both cases, highlighting how the orientation of the panels alone dramatically changes the overall aesthetic impact. The horizontal cladding might feel more grounded and inviting, while the vertical cladding conveys a sense of modern elegance and height.

Warranty and Customer Support

Source: made-in-china.com

We understand that investing in your home’s exterior is a significant decision, so Everlast polymeric cladding comes with a comprehensive warranty designed to protect your investment and provide peace of mind. This section details the warranty coverage, the claims process, and the resources available to assist you.

Everlast polymeric cladding is backed by a [Insert Number] year-limited warranty against manufacturing defects in materials and workmanship. This warranty covers issues such as cracking, peeling, fading, and delamination, provided the product has been installed and maintained according to the manufacturer’s instructions. Specific exclusions, such as damage caused by improper installation, acts of God, or vandalism, are Artikeld in the full warranty document, which is provided at the time of purchase and is also available on our website.

Warranty Claim Process

Filing a warranty claim is straightforward. First, gather photographic evidence of the defect and carefully document the location and extent of the damage. Next, contact our customer support team via phone or email (contact details below). They will guide you through the process, which may involve submitting photographic evidence, a copy of your purchase receipt, and a completed warranty claim form. Once received, our team will review your claim and contact you within [Number] business days to inform you of the next steps. Approved claims will typically result in the repair or replacement of the affected cladding panels.

Customer Support Resources

We are committed to providing excellent customer support throughout the lifespan of your Everlast polymeric cladding. You can reach us through several convenient channels:

- Phone: [Insert Phone Number]

- Email: [Insert Email Address]

- Website: [Insert Website Address] – Our website features a comprehensive FAQ section, installation guides, and a contact form for submitting inquiries.

Frequently Asked Questions

We anticipate you may have some questions regarding Everlast polymeric cladding. To help you, we’ve compiled a list of frequently asked questions and their answers.

- Question: How long does the warranty last?

Answer: The Everlast polymeric cladding warranty is valid for [Insert Number] years from the date of purchase. - Question: What does the warranty cover?

Answer: The warranty covers manufacturing defects in materials and workmanship, including cracking, peeling, fading, and delamination, under normal use and maintenance conditions. Refer to the full warranty document for complete details and exclusions. - Question: What if my cladding is damaged due to an act of God (e.g., a hurricane)?

Answer: Damage caused by acts of God, vandalism, or improper installation is generally not covered under the warranty. Contact your homeowner’s insurance provider for potential coverage. - Question: How long does it take to process a warranty claim?

Answer: We aim to review your claim within [Number] business days of receiving all necessary documentation. The timeline for repairs or replacements may vary depending on the nature and extent of the damage and parts availability. - Question: What if I have a question not addressed here?

Answer: Please don’t hesitate to contact our customer support team via phone, email, or through our website’s contact form. We are happy to assist you.

Last Word

Everlast polymeric cladding presents a compelling option for modern construction, balancing durability, aesthetics, and sustainability. Its versatility in design, ease of maintenance, and potential for long-term cost savings make it a worthwhile investment. Whether you’re considering it for a residential renovation, commercial development, or industrial project, understanding its properties and application will ensure a successful and visually stunning outcome. This guide has aimed to provide a complete picture, but remember to consult with professionals for specific project requirements and installations.

FAQ Overview

Is Everlast polymeric cladding fire-resistant?

While not inherently fireproof, Everlast polymeric cladding typically possesses a fire-retardant rating, though the specific rating will vary depending on the exact product and formulation. Check the manufacturer’s specifications for details.

Can Everlast polymeric cladding be painted?

Generally, no. The cladding’s color is integrated during the manufacturing process. Painting is usually not recommended and may void any warranty.

What is the warranty period for Everlast polymeric cladding?

Warranty periods vary by manufacturer and product line. Always check the specific warranty information provided by the supplier before purchase.

How often should Everlast polymeric cladding be cleaned?

Regular cleaning, typically once or twice a year depending on the climate and environment, is recommended to maintain its appearance and prevent dirt buildup. Use a mild detergent and water, avoiding harsh chemicals.

Is Everlast polymeric cladding suitable for all climates?

While durable, the suitability of Everlast polymeric cladding depends on the specific product and its resistance to extreme temperature fluctuations, UV radiation, and moisture. Consult the manufacturer for climate-specific suitability information.

Comments are closed.