Everlast Cladding A Comprehensive Guide

Everlast cladding offers a durable and stylish exterior solution for both residential and commercial projects. This guide dives deep into its various applications, installation, maintenance, cost-effectiveness, and environmental impact, providing you with all the information you need to make an informed decision. We’ll explore the different materials, highlighting their unique properties and benefits, and compare Everlast cladding to other options on the market. Get ready to discover why Everlast cladding is a top choice for modern construction.

From choosing the right material for your specific needs to understanding the installation process and long-term maintenance, this guide covers everything you need to know. We’ll also explore the financial aspects, including cost comparisons and return on investment, and delve into the environmental considerations of choosing Everlast cladding. Let’s get started!

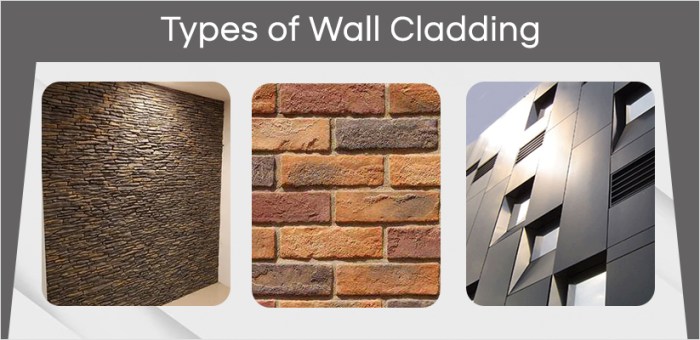

Everlast Cladding Product Overview

Everlast cladding offers a durable and aesthetically pleasing exterior solution for various building types. Its range of materials and customizable options cater to diverse architectural styles and project requirements. This section details the product range, manufacturing process, and key features of different Everlast cladding types.

Everlast Cladding Materials

Everlast cladding is available in a variety of materials, each offering unique properties and benefits. The most common materials include aluminum composite material (ACM), high-pressure laminate (HPL), and fiber cement. These materials are chosen for their durability, weather resistance, and low maintenance requirements. The specific composition of each material contributes to its performance characteristics, such as resistance to impact, UV degradation, and fire. For example, ACM panels are known for their lightweight yet strong nature, while fiber cement offers superior fire resistance.

Everlast Cladding Manufacturing Process

The manufacturing process for Everlast cladding involves several key steps, ensuring high-quality and consistent products. It begins with the selection and preparation of raw materials. For ACM, this involves aluminum sheets and a polyethylene core. These materials are then precisely cut and layered, often with a decorative finish applied. High-pressure laminates involve layering kraft paper, decorative paper, and resin under immense pressure and heat. For fiber cement, a mixture of cement, cellulose fibers, and other additives is formed into panels, cured, and then often coated for enhanced protection and aesthetics. Quality control measures are implemented throughout the process to ensure dimensional accuracy, surface finish, and overall performance.

Comparison of Everlast Cladding Types

The following table compares the features, benefits, and applications of different Everlast cladding materials:

| Material | Thickness (mm) | Color Options | Durability Rating | Warranty (Years) |

|---|---|---|---|---|

| Aluminum Composite Material (ACM) | 2-6 | A wide range, of custom colors, is available | High; excellent resistance to weathering and impact | 10-20 (varies by manufacturer and specific product) |

| High-Pressure Laminate (HPL) | 0.8-12 | Extensive range, including wood grain and stone effects | High; resistant to scratches, stains, and moisture | 10-25 (varies by manufacturer and specific product) |

| Fiber Cement | 8-16 | Limited color range, often requiring painting | Very High; fire-resistant, durable, and long-lasting | 20-50 (varies by manufacturer and specific product) |

Everlast Cladding Applications

Everlast cladding, with its durability and aesthetic versatility, finds application in a wide range of projects, from cozy homes to imposing commercial structures. Its adaptability allows for seamless integration into diverse architectural styles, offering a blend of modern aesthetics and long-lasting performance. Let’s explore some examples.

Residential Applications of Everlast Cladding

Everlast cladding provides a striking and durable exterior for residential projects. Imagine a modern farmhouse, it’s crisp white Everlast cladding contrasting beautifully with dark-framed windows and a natural stone base. The clean lines of the cladding accentuate the home’s architectural details, creating a sophisticated yet inviting façade. The cladding’s low-maintenance nature is a significant advantage for homeowners, minimizing upkeep and maximizing enjoyment. Another example might be a contemporary beach house, where the cladding’s resilience to harsh weather conditions—salt spray and strong winds—makes it an ideal choice. The light grey Everlast panels, perhaps with a subtle wood grain texture, would complement the coastal setting, creating a sense of relaxed elegance. In a mountainous region, a darker shade of Everlast cladding might blend seamlessly with the surrounding landscape, offering a protective layer against the elements while enhancing the home’s aesthetic integration.

Commercial Applications of Everlast Cladding

The robust nature and aesthetic appeal of Everlast cladding extends beyond residential projects. Consider a modern office building, its sleek façade clad in dark grey Everlast panels. The panels’ smooth surface reflects light, giving the building a sophisticated and contemporary look. The consistent color and texture create a unified aesthetic, enhancing the building’s professional image. A retail complex might utilize Everlast cladding in a variety of colors and patterns to create visual interest and brand differentiation. Imagine a vibrant shopping center, where different sections are clad in contrasting shades of Everlast, each section reflecting the individual brand identity of the stores within. The durability of the cladding ensures that the building maintains its appearance for years to come, minimizing the need for costly repairs and maintenance. Another example could be a multi-story parking garage, where Everlast cladding could be used to improve the building’s overall aesthetic, masking its functional purpose and creating a more welcoming and less industrial appearance.

Suitability for Various Architectural Styles

Everlast cladding’s adaptability makes it suitable for a wide range of architectural styles. Its clean lines and modern aesthetic make it a perfect choice for contemporary designs, while its ability to mimic the look of natural materials, such as wood or stone, allows for integration into more traditional styles. For instance, Everlast cladding can easily replicate the appearance of wood siding on a craftsman-style home, providing the beauty of wood without maintenance. Similarly, it can be used to create a stone-like façade on a rustic building, offering a durable and weather-resistant alternative to natural stone. The flexibility in color and texture options allows architects to tailor the cladding to the specific requirements of each project, ensuring a harmonious blend of form and function. The cladding’s versatility also extends to modern industrial designs, where its sleek, minimalist aesthetic can enhance the building’s clean lines and geometric forms.

Modern Building Facade Design Mock-up

Imagine a multi-story apartment building with a modern, minimalist design. The façade is clad in light grey Everlast panels, creating a clean, seamless look. The panels are arranged in a vertical orientation, emphasizing the building’s height and slender profile. Large windows, framed in dark grey metal, are strategically placed to maximize natural light and offer stunning views of the cityscape. Balconies, with glass railings, are incorporated into the design, providing residents with private outdoor spaces. The overall effect is one of sophisticated elegance and modern functionality. The choice of light grey Everlast cladding provides a neutral backdrop, allowing the architectural details and surrounding environment to take center stage. The contrast between the light grey cladding and the dark grey window frames adds visual interest without overwhelming the design. This choice reflects a modern aesthetic, prioritizing clean lines and a minimalist approach to maximize the building’s visual impact.

Everlast Cladding Installation and Maintenance

Source: kiosparquet-jakarta.com

Getting Everlast cladding installed correctly is key to enjoying its long-term benefits. Proper installation ensures a durable, weather-resistant, and aesthetically pleasing finish. This section details the process, necessary tools, safety precautions, and a maintenance schedule to keep your cladding looking its best for years to come.

Installation Steps

This step-by-step guide provides a general overview. Always refer to the manufacturer’s specific installation instructions for your Everlast cladding product. Variations in panel types and configurations will require adjustments to this general process.

- Preparation: Begin by carefully measuring and planning the cladding layout. This includes accounting for any cuts, overlaps, and expansion gaps needed for thermal movement. Ensure the underlying structure is properly prepared and leveled. Any imperfections in the substrate will show through the cladding.

- Framing (if necessary): Depending on the type of Everlast cladding and the application, you may need to install a supporting framework. This framework must be sturdy, level, and plumb to provide a stable base for the cladding panels.

- Panel Installation: Start at a corner or a designated starting point, and install the panels according to the manufacturer’s instructions. This usually involves fastening the panels securely to the framing or substrate using appropriate fasteners. Ensure consistent spacing and alignment throughout the installation process.

- Cutting and Finishing: Precise cutting may be required to fit the cladding around corners, windows, and other features. Use appropriate cutting tools and techniques to avoid damaging the panels. Properly seal any cuts or seams to maintain water tightness.

- Final Inspection: After installation, conduct a thorough inspection to ensure all panels are securely fastened, aligned correctly, and free from damage. Check for any gaps or inconsistencies that need to be addressed.

Necessary Tools and Equipment

Having the right tools will make the installation process smoother and more efficient. This list includes common items, but specific requirements may vary depending on the cladding type and project scale.

- Measuring tape

- Level

- Drill with appropriate drill bits

- Screwdriver (or impact driver)

- Safety glasses

- Work gloves

- Cutting tools (e.g., circular saw, jigsaw, shears – depending on the cladding material)

- Caulk gun and sealant

- Ladder (if necessary)

- Scaffolding (for larger projects)

Safety Precautions

Safety should be the top priority during any installation project. Ignoring safety can lead to serious injury.

- Always wear appropriate personal protective equipment (PPE), including safety glasses, work gloves, and sturdy footwear.

- Use caution when working at heights. Use appropriate fall protection equipment if necessary.

- Be aware of overhead power lines and other potential hazards.

- Follow all manufacturer’s instructions and safety guidelines.

- Ensure proper ventilation in enclosed spaces.

- Dispose of waste materials properly.

Maintenance Schedule

Regular maintenance will extend the life and beauty of your Everlast cladding.

- Annual Inspection: Conduct a visual inspection at least once a year to check for any signs of damage, such as cracks, loose panels, or discoloration.

- Cleaning: Clean the cladding regularly using a soft brush, mild detergent, and water. Avoid harsh chemicals or abrasive cleaners that could damage the surface. For stubborn stains, consult the manufacturer’s cleaning recommendations.

- Repair: Address any damage promptly. Minor repairs, such as replacing a damaged panel, may be possible with DIY skills. For extensive damage, consult a professional installer.

Everlast Cladding Durability and Longevity

Everlast cladding is designed for exceptional durability and longevity, significantly outperforming many traditional cladding materials. Its robust construction and advanced materials contribute to its long lifespan, offering a cost-effective solution in the long run due to reduced maintenance and replacement needs. This section will delve into the specifics of its lifespan, performance in various weather conditions, potential vulnerabilities, and the manufacturer’s warranty.

Everlast cladding boasts a significantly longer lifespan compared to many common alternatives. For example, while wood cladding might require repainting or replacement every 10-15 years due to weathering and rot, and vinyl siding can become brittle and fade within 20 years, Everlast cladding is engineered to resist these issues for a much extended period. The exact lifespan will depend on factors such as installation quality and environmental conditions, but manufacturers often cite a lifespan exceeding 50 years with proper care. This longevity translates to significant long-term cost savings.

Lifespan Comparison with Other Cladding Materials

The following table compares the typical lifespan of Everlast cladding with other popular options:

| Cladding Material | Estimated Lifespan (Years) | Maintenance Requirements |

|---|---|---|

| Everlast Cladding | 50+ | Minimal; occasional cleaning |

| Wood Cladding | 10-15 | Regular painting, staining, and potential repairs |

| Vinyl Siding | 20-30 | Occasional cleaning; prone to cracking and fading |

| Aluminum Siding | 30-40 | Cleaning; susceptible to dents and scratches |

Impact of Weather Conditions on Everlast Cladding Performance

Everlast cladding is designed to withstand a wide range of weather conditions. Its resistance to UV radiation prevents fading and discoloration, while its robust construction protects against impact damage from hail or debris. The material’s inherent properties also make it highly resistant to moisture penetration, reducing the risk of rot, mold, and mildew, even in regions with high humidity or frequent rainfall. However, extreme weather events, such as hurricanes or tornadoes, can potentially cause damage, regardless of the cladding material used. Proper installation according to manufacturer guidelines is crucial to maximize its performance in all weather conditions.

Potential Issues and Vulnerabilities

While highly durable, Everlast cladding is not impervious to all issues. Improper installation can lead to leaks or gaps that compromise its weather resistance. Damage from severe impacts, such as falling branches or vehicle collisions, can also occur. Furthermore, while resistant to fading, prolonged exposure to intense UV radiation over many decades might eventually lead to some minor color changes. Regular inspection and prompt addressing of any potential issues are recommended to maintain the cladding’s integrity and longevity.

Manufacturer’s Warranty

The manufacturer typically provides a comprehensive warranty covering defects in materials and workmanship for a specified period, often ranging from 25 to 50 years. This warranty typically covers issues such as cracking, peeling, and fading caused by manufacturing defects. It’s essential to carefully review the specific terms and conditions of the warranty provided with your Everlast cladding purchase to understand the exact coverage and limitations. The warranty usually does not cover damage resulting from improper installation, vandalism, or acts of God.

Everlast Cladding Cost and Value

Choosing the right cladding material involves careful consideration of both upfront costs and long-term value. Everlast cladding, while potentially representing a higher initial investment compared to some alternatives, often offers significant advantages in terms of durability, maintenance, and lifespan, ultimately leading to a strong return on investment. Let’s explore the factors influencing the cost and the overall value proposition.

Cost Factors in Everlast Cladding Projects

Several factors contribute to the overall cost of an Everlast cladding project. These include the size and complexity of the project, the specific Everlast cladding chosen (different profiles and finishes have varying price points), the labor costs associated with installation, and any necessary preparatory work, such as substrate preparation or demolition of existing cladding. Additional costs may include transportation, permits, and any specialized tools or equipment required for installation. It’s crucial to obtain detailed quotes from reputable Everlast installers to accurately assess the total project cost.

Everlast Cladding’s Initial Cost vs. Long-Term Value

While the initial investment in Everlast cladding might seem higher than some cheaper alternatives like vinyl or wood, the long-term value proposition is compelling. Everlast’s superior durability significantly reduces the need for frequent repairs and replacements, a common and costly issue with less durable materials. This translates to substantial savings over the building’s lifespan. Furthermore, the low maintenance requirements of Everlast cladding minimize ongoing costs associated with cleaning, painting, or other upkeep.

Return on Investment (ROI) of Everlast Cladding

The ROI of Everlast cladding can be calculated by comparing the total cost of the project (including installation and any preparatory work) to the long-term savings achieved through reduced maintenance and extended lifespan. For example, a building owner might invest $50,000 in Everlast cladding, but avoid $10,000 in repairs and replacements over 20 years that would be necessary with less durable material. This represents a significant return on their initial investment. Moreover, the enhanced aesthetic appeal and increased property value resulting from Everlast cladding can contribute to a positive ROI. Accurate ROI calculations require careful consideration of all relevant costs and potential savings over the expected lifespan of the cladding.

Cost Comparison of Cladding Materials, Everlast cladding

The following table offers a hypothetical cost comparison for different cladding materials, highlighting the relative cost and potential long-term value. Note that these are illustrative figures and actual costs can vary depending on factors such as project size, location, and installer.

| Cladding Material | Initial Cost (per sq ft) | Estimated Lifespan (years) | Maintenance Costs (per year, per sq ft) |

|---|---|---|---|

| Everlast Cladding | $15 – $25 | 50+ | $0.10 – $0.50 |

| Vinyl Siding | $5 – $10 | 15-20 | $0.50 – $1.00 |

| Wood Siding | $8 – $18 | 10-20 | $1.00 – $3.00 |

| Aluminum Siding | $7 – $15 | 30-40 | $0.25 – $0.75 |

Everlast Cladding Environmental Impact

Source: mccoymart.com

Everlast cladding’s environmental impact is a key consideration for environmentally conscious builders and designers. This section details the material’s sustainability credentials, comparing it to alternatives and highlighting relevant certifications. Understanding this impact allows for informed decisions aligned with green building principles.

Everlast cladding materials boast several environmentally friendly attributes. The specific composition of Everlast cladding (which needs to be specified by the manufacturer for accurate assessment) will dictate the precise environmental impact. For example, if it’s composed of recycled materials, this significantly reduces its environmental footprint compared to cladding made from virgin resources. Similarly, the manufacturing process itself plays a crucial role; a process with minimal waste and energy consumption leads to a lower overall impact.

Recyclability and Sustainability

The recyclability and sustainability of Everlast cladding are directly related to its composition. Many modern cladding materials incorporate recycled content and are designed for end-of-life recycling. However, the ease and effectiveness of recycling vary greatly depending on the specific material and the available recycling infrastructure. For example, some Everlast cladding options might be easily disassembled and their components recycled separately, while others might require specialized processing. It’s crucial to check the manufacturer’s specifications and local recycling capabilities for detailed information on the recyclability of a particular Everlast cladding product. The use of sustainable materials in the manufacturing process, such as rapidly renewable timber or recycled aluminum, also contributes to the overall sustainability of the product.

Carbon Footprint Comparison

Comparing the carbon footprint of Everlast cladding to alternatives requires a detailed life cycle assessment (LCA). An LCA considers the environmental impacts of a product across its entire life, from material extraction to disposal. Different cladding materials, such as wood, metal, concrete, and fiber cement, have varying carbon footprints. Generally, materials with high embodied energy (energy used in manufacturing) have larger carbon footprints. For instance, aluminum cladding often has a higher carbon footprint due to the energy-intensive aluminum production process. However, Everlast cladding, depending on its specific composition and manufacturing process, may offer a lower carbon footprint compared to some alternatives, particularly if it incorporates recycled materials or utilizes sustainable manufacturing techniques. This comparison is best made by consulting the manufacturer’s LCA data or independent LCA studies for specific Everlast cladding products and comparing them to data for competing materials.

Certifications and Eco-labels

Several certifications and eco-labels can indicate a product’s environmental performance. Examples include LEED (Leadership in Energy and Environmental Design) points for sustainable building materials and certifications from organizations like the Forest Stewardship Council (FSC) for wood-based materials. The presence of these certifications on Everlast cladding products would demonstrate a commitment to environmental responsibility and provide verifiable evidence of the material’s sustainability credentials. Checking the manufacturer’s website or contacting them directly will provide information on any certifications or eco-labels associated with specific Everlast cladding products. The availability of such certifications can significantly enhance the credibility of the product’s environmental claims.

Closing Notes

Source: newtechmachinery.com

Everlast cladding presents a compelling option for those seeking a durable, aesthetically pleasing, and environmentally conscious exterior solution. By understanding its diverse applications, installation procedures, maintenance requirements, and long-term value, you can confidently assess its suitability for your project. This guide has equipped you with the knowledge to make an informed decision, ensuring your building project achieves both beauty and longevity. Remember to always consult with professionals for specific project needs and installation guidance.

Clarifying Questions

What is the warranty on Everlast cladding?

Warranty details vary depending on the specific Everlast cladding product and its material. Check the manufacturer’s specifications for exact coverage.

Can Everlast cladding be used in all climates?

While Everlast cladding is designed for durability, performance can vary based on climate. Consult the manufacturer’s guidelines for suitability in your specific region.

How often should Everlast cladding be cleaned?

Regular cleaning, typically once or twice a year, helps maintain its appearance and longevity. Use a mild detergent and water; avoid abrasive cleaners.

Is Everlast cladding recyclable?

Recyclability depends on the specific Everlast cladding material. Check the manufacturer’s information on responsible disposal and recycling options.

What are the potential drawbacks of Everlast cladding?

Potential drawbacks might include initial cost (compared to cheaper alternatives), potential for damage from extreme impacts, and the need for professional installation.

Comments are closed.